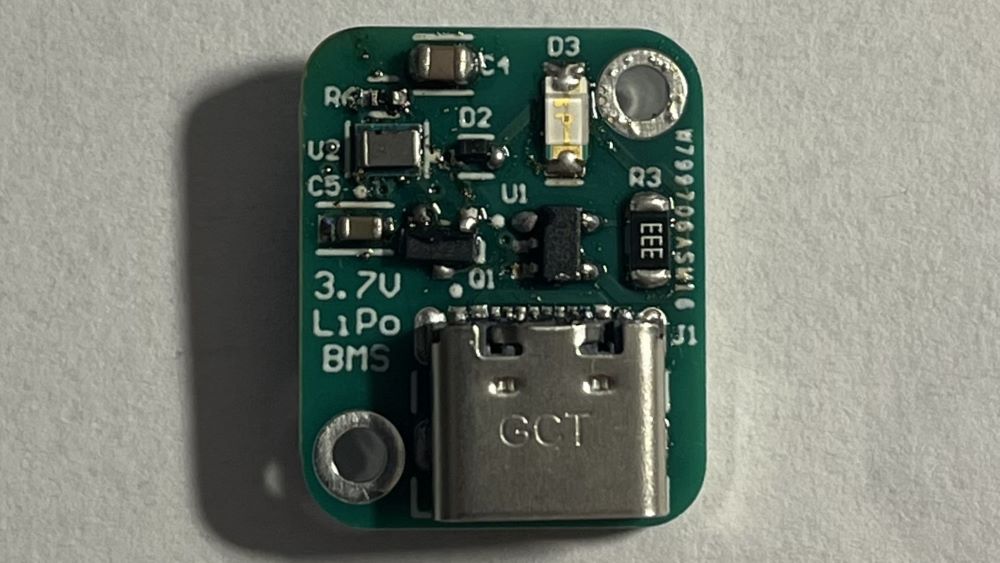

3.7V LiPo BMS

Circuit Board

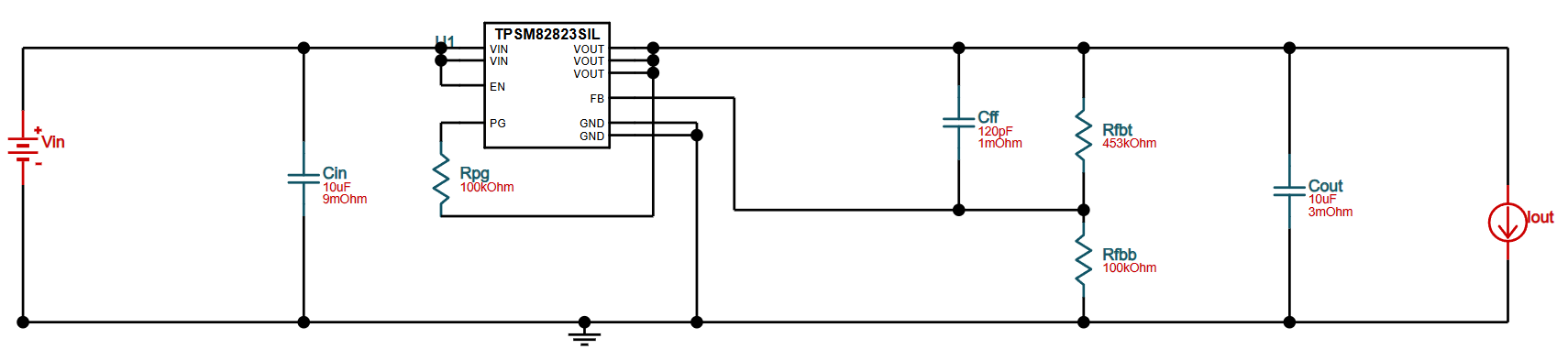

This PCB I designed manages the charging of a 3.7V LiPo battery. When powered by USB-C, the board is capable of load sharing, powering the load connected to the board in addition to charging the battery simultaneously. Seemlessly, the board, when unplugged, the board switches to powering the load off of the LiPo battery until the battery is depleeted. The board also has a WEBENCH-designed buck converter outputting 3.3V during both USB-C power and off the LiPo.

This project is sponsored by PCBWay, a wonderful and easy to use PCB manufacturer.