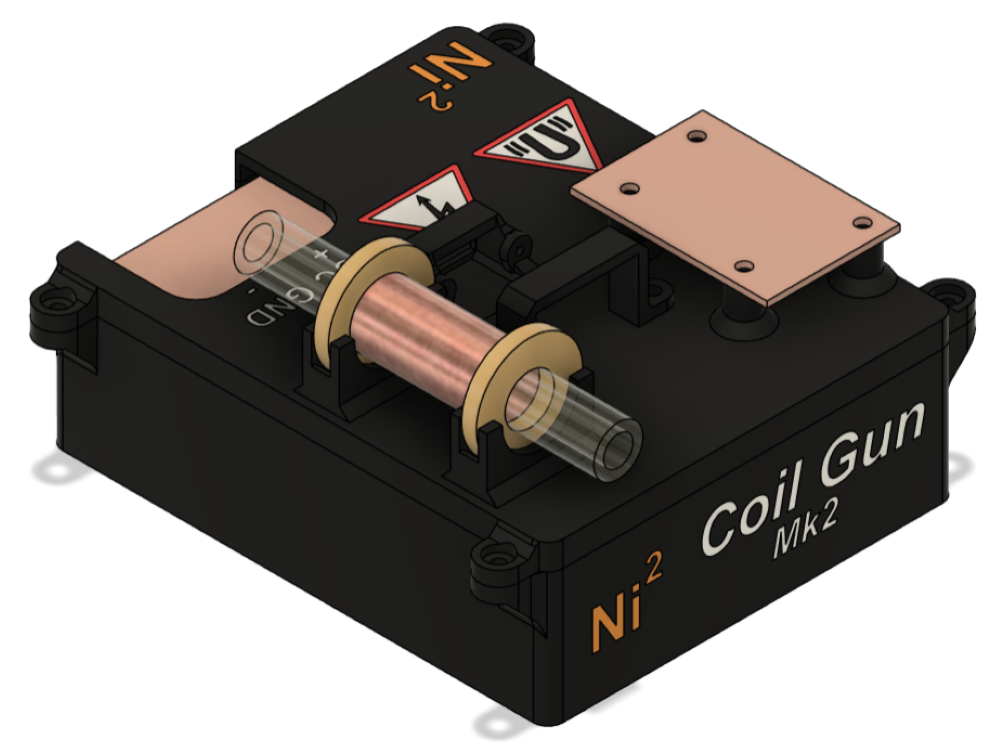

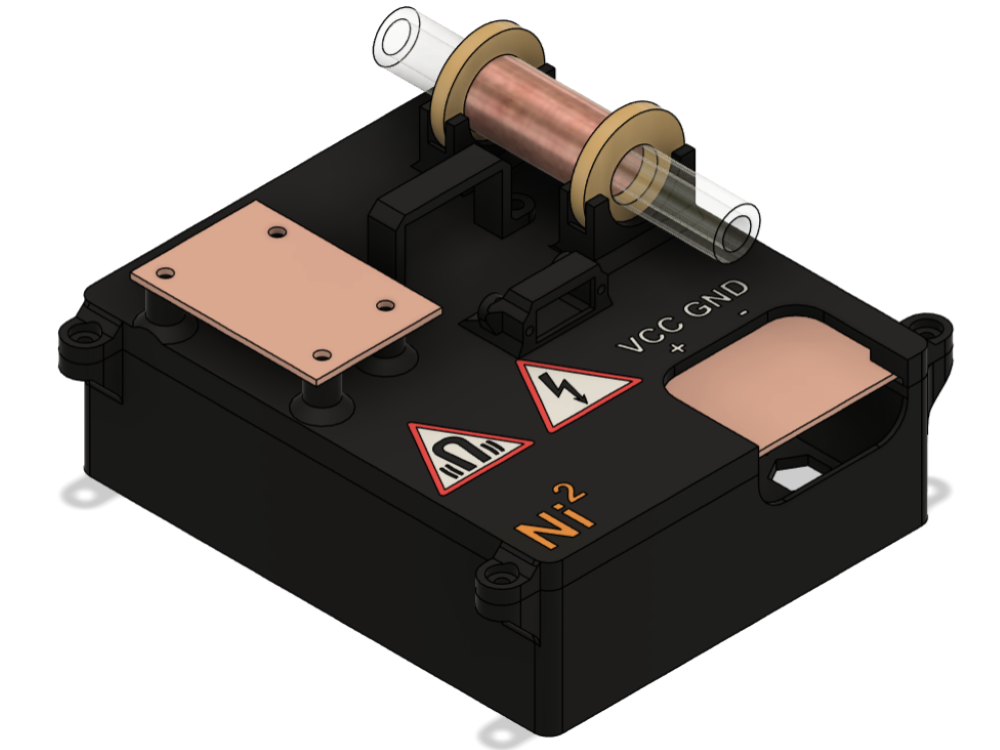

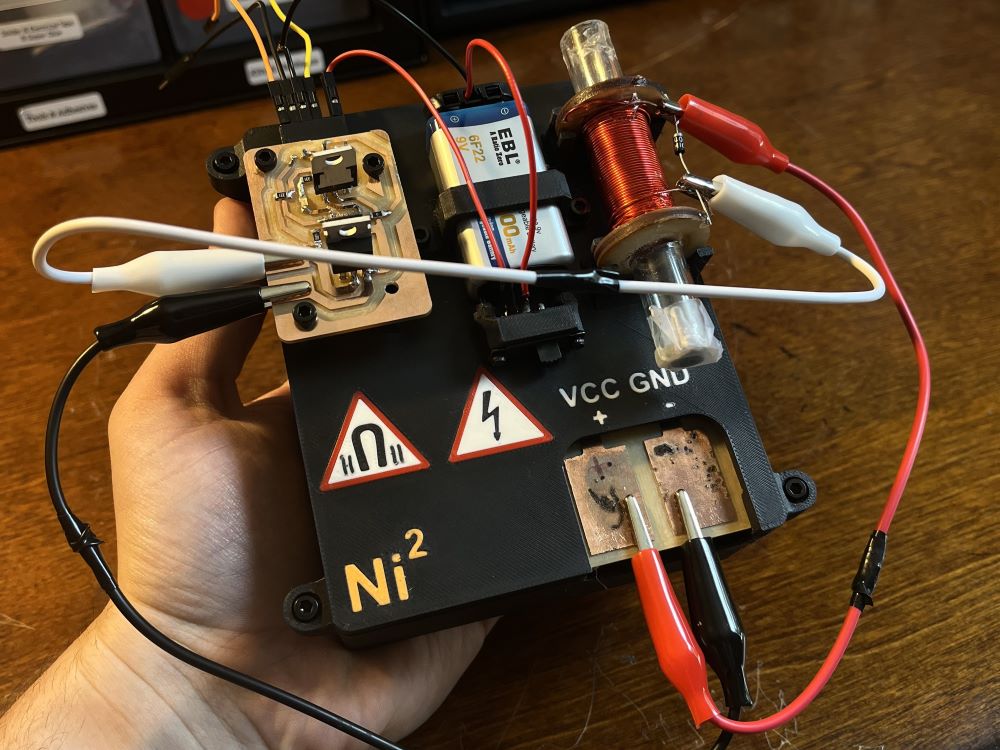

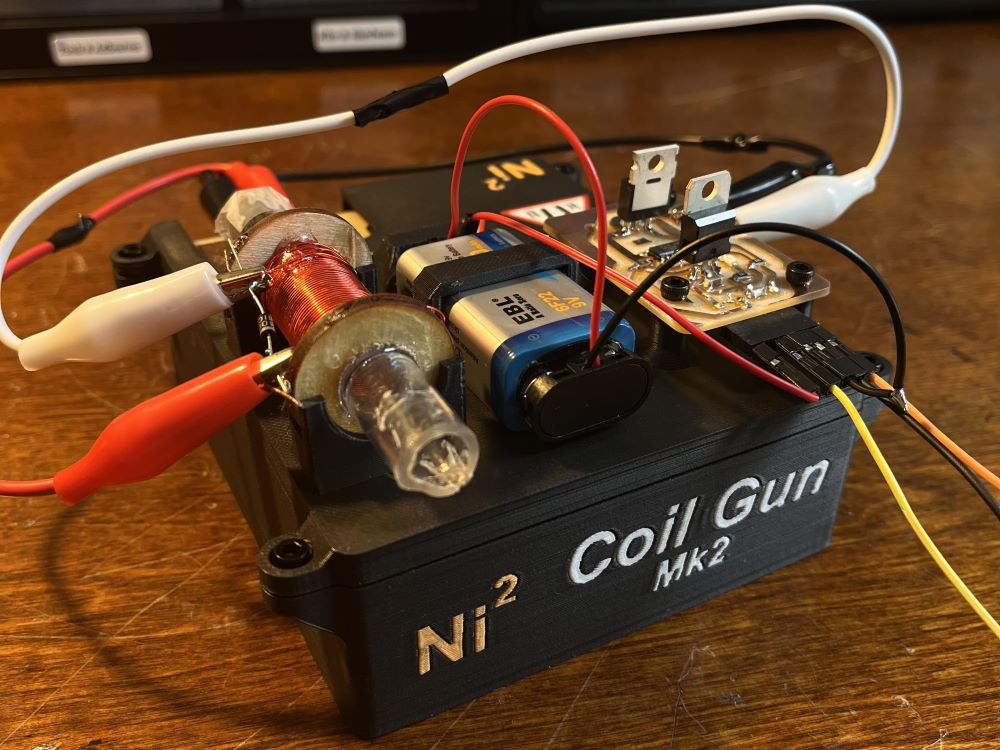

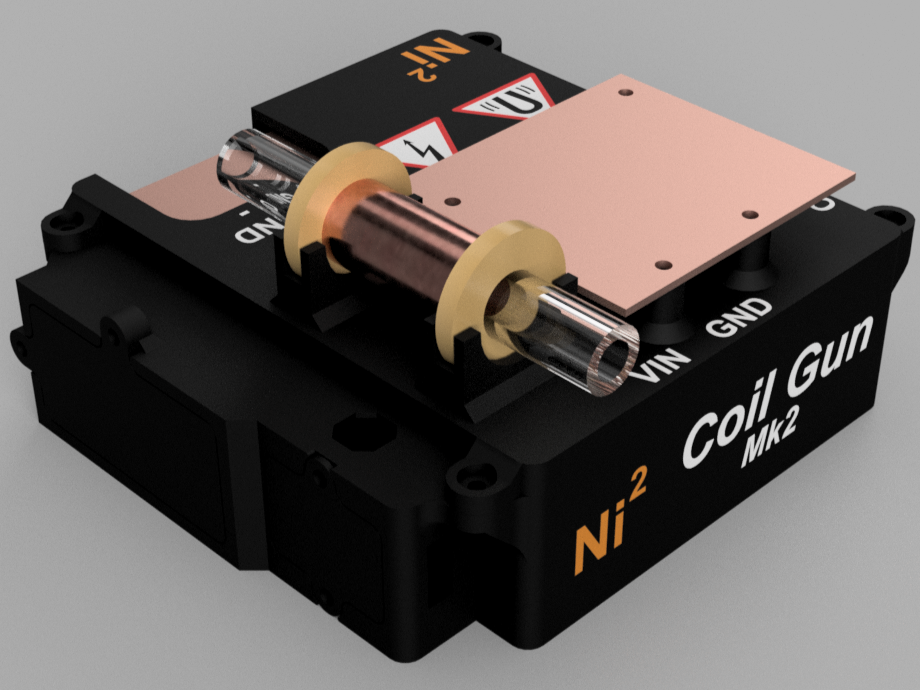

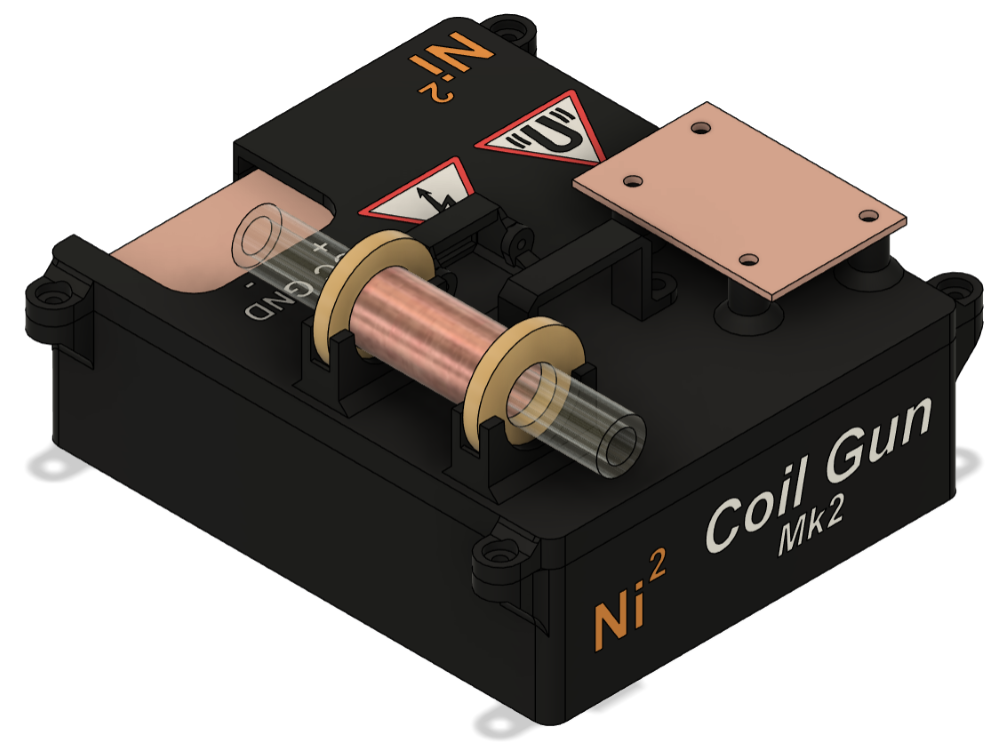

Coil Gun Mk. 2

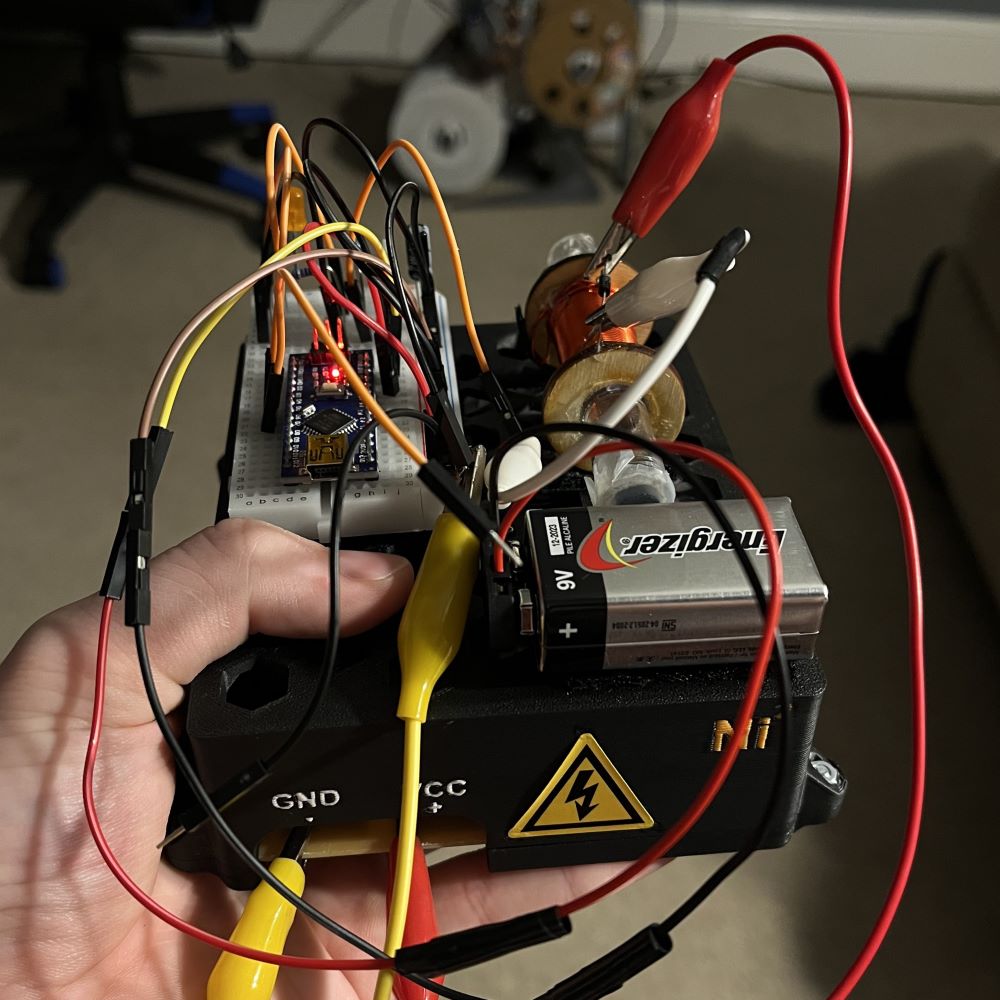

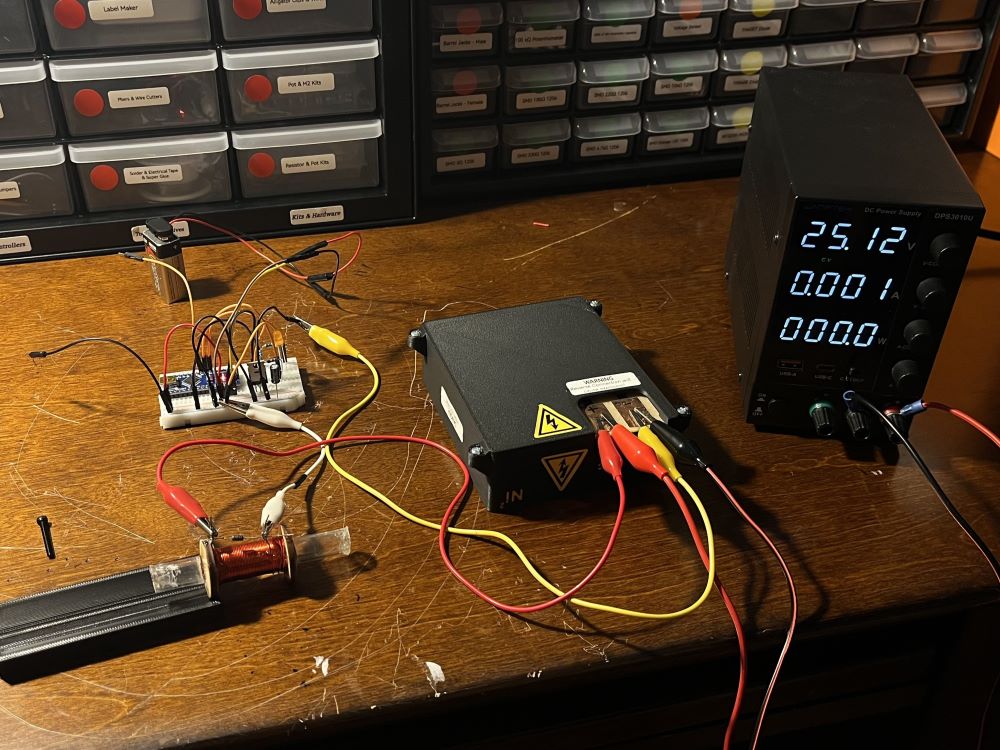

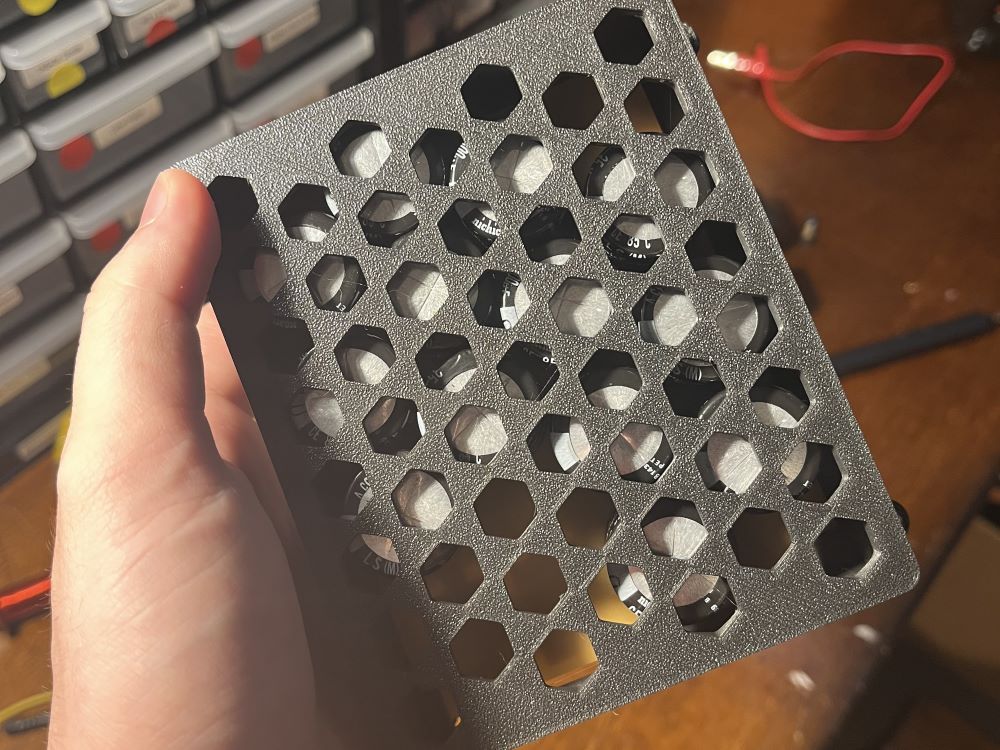

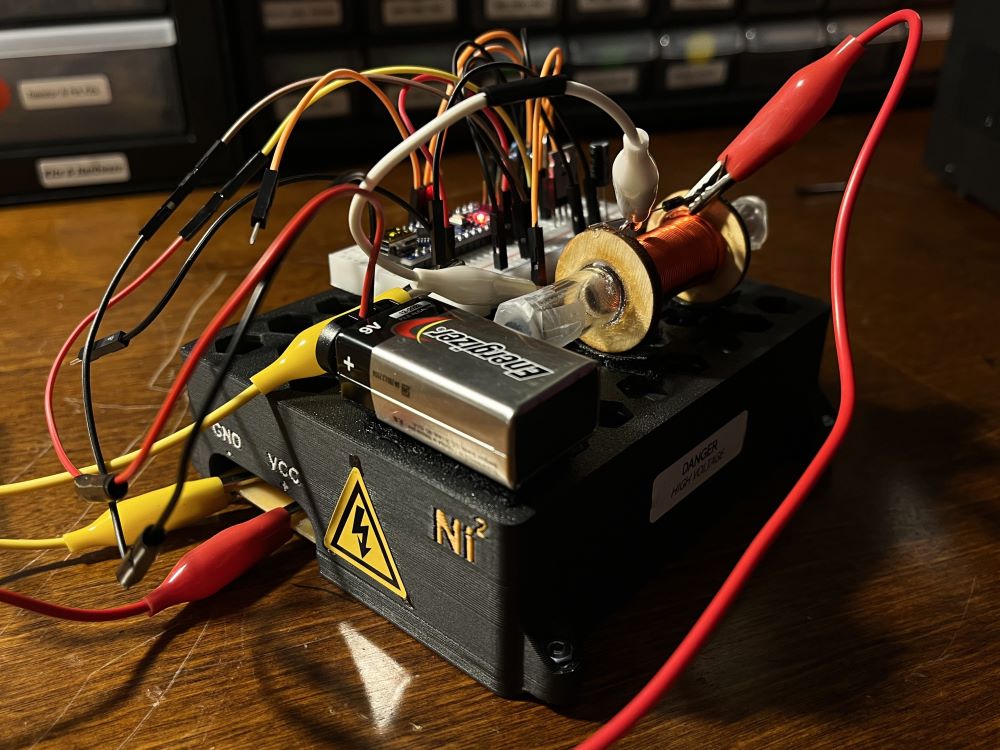

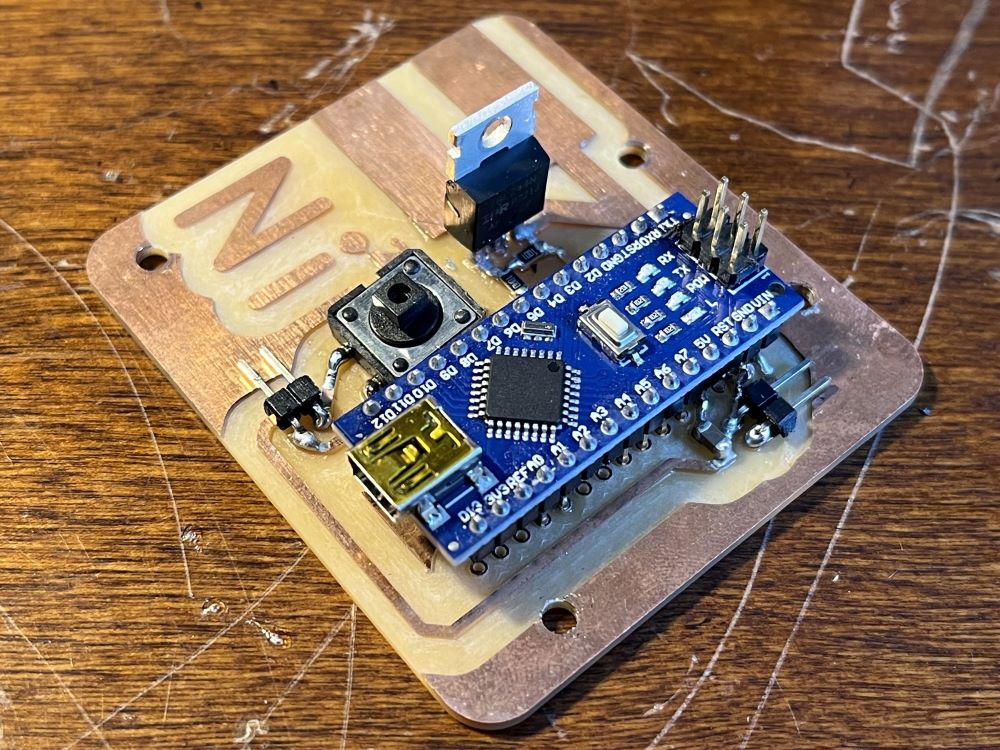

Device

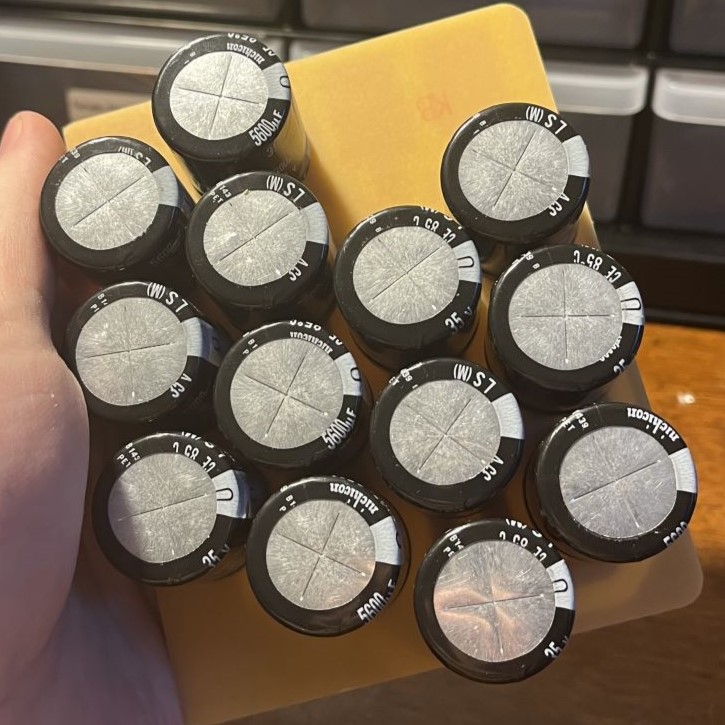

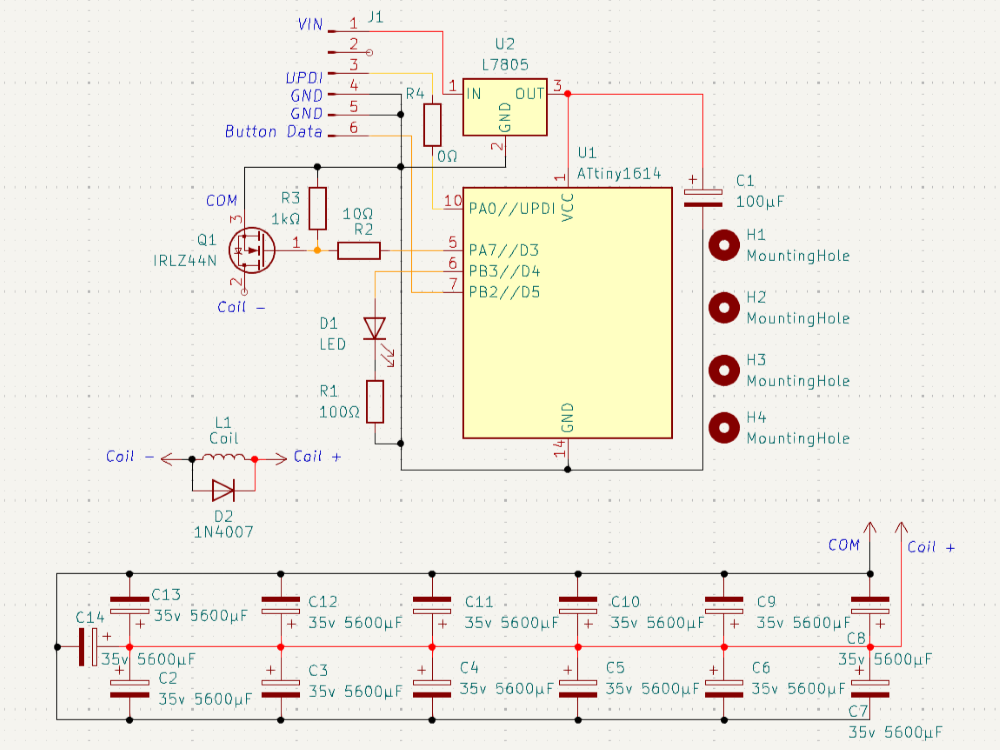

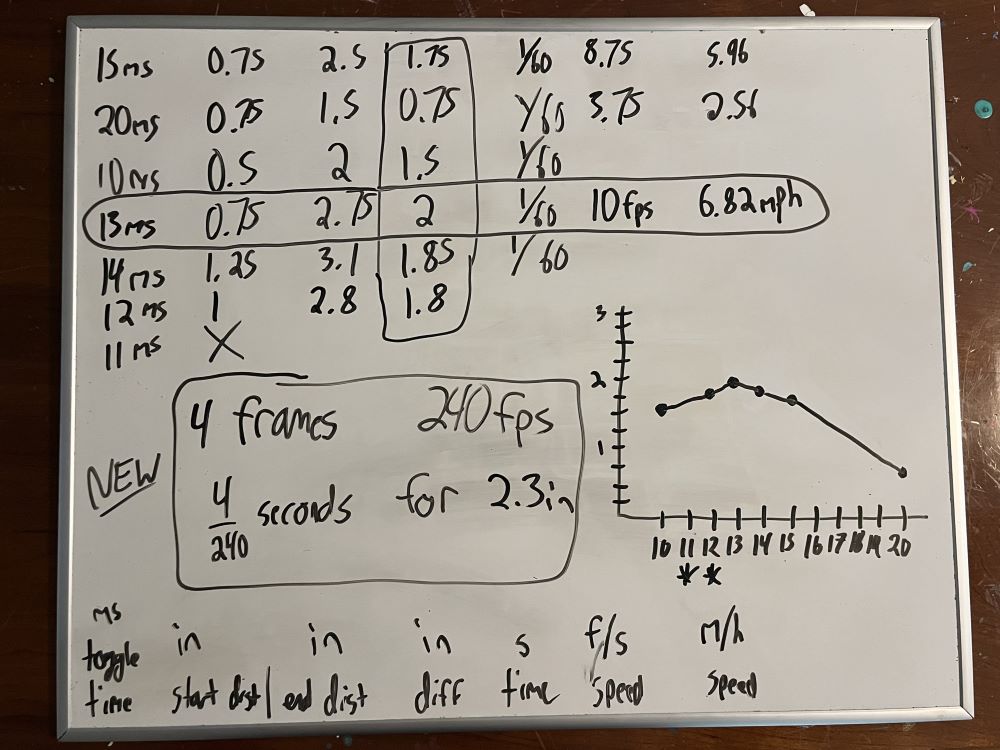

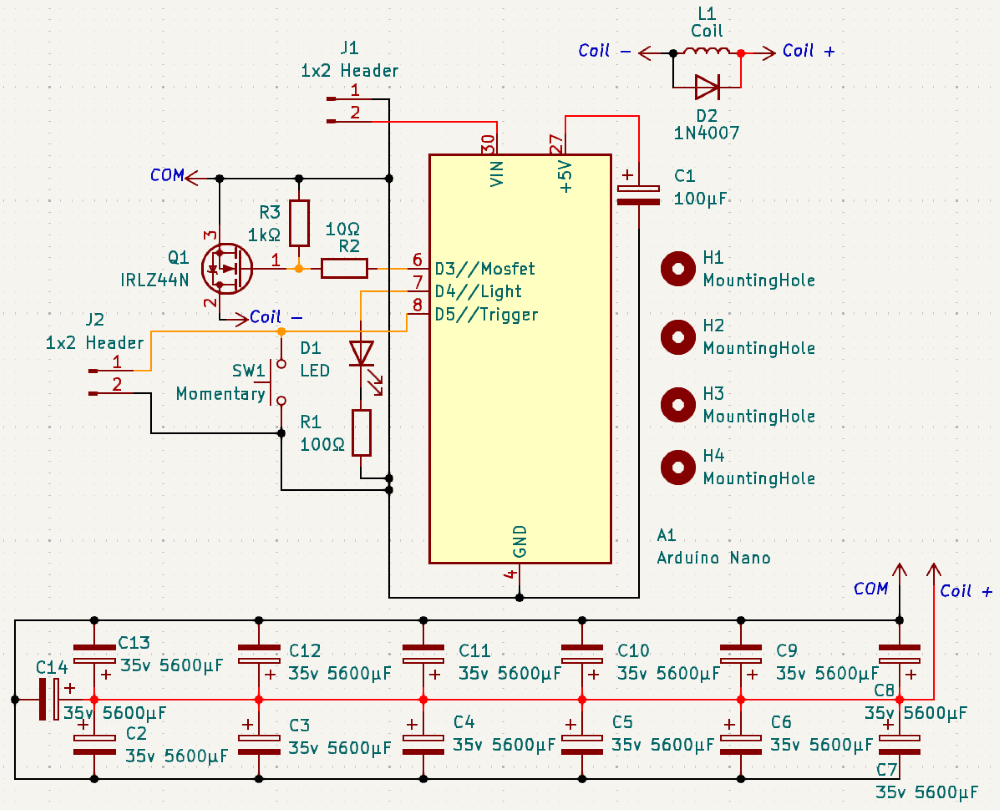

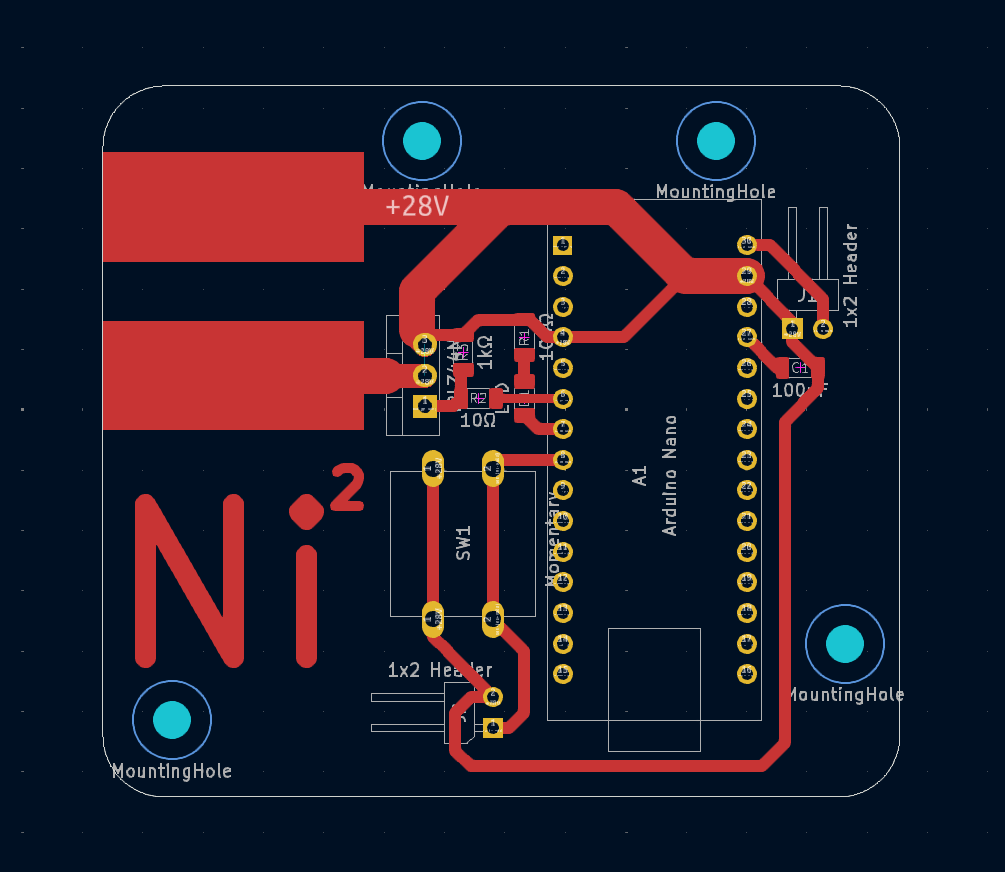

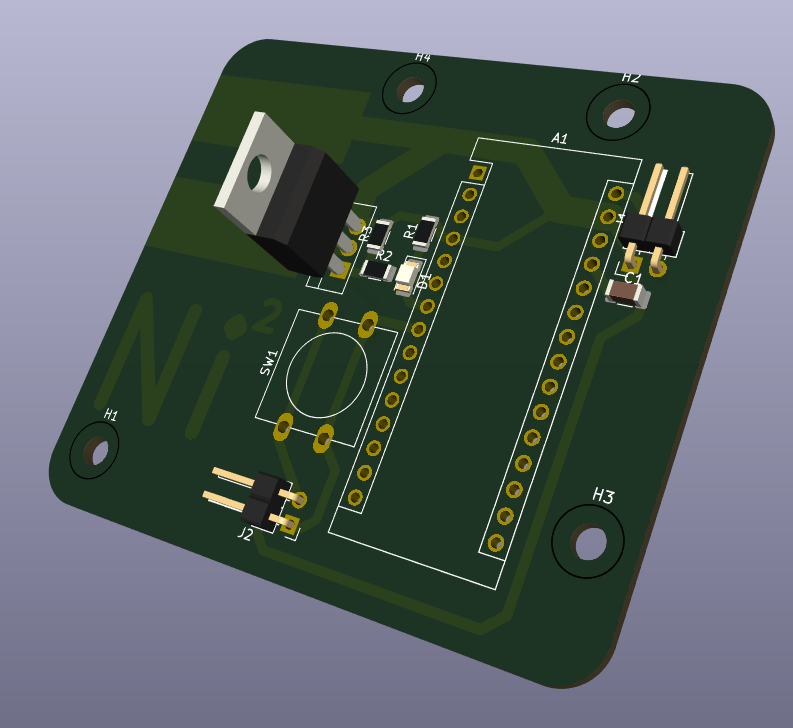

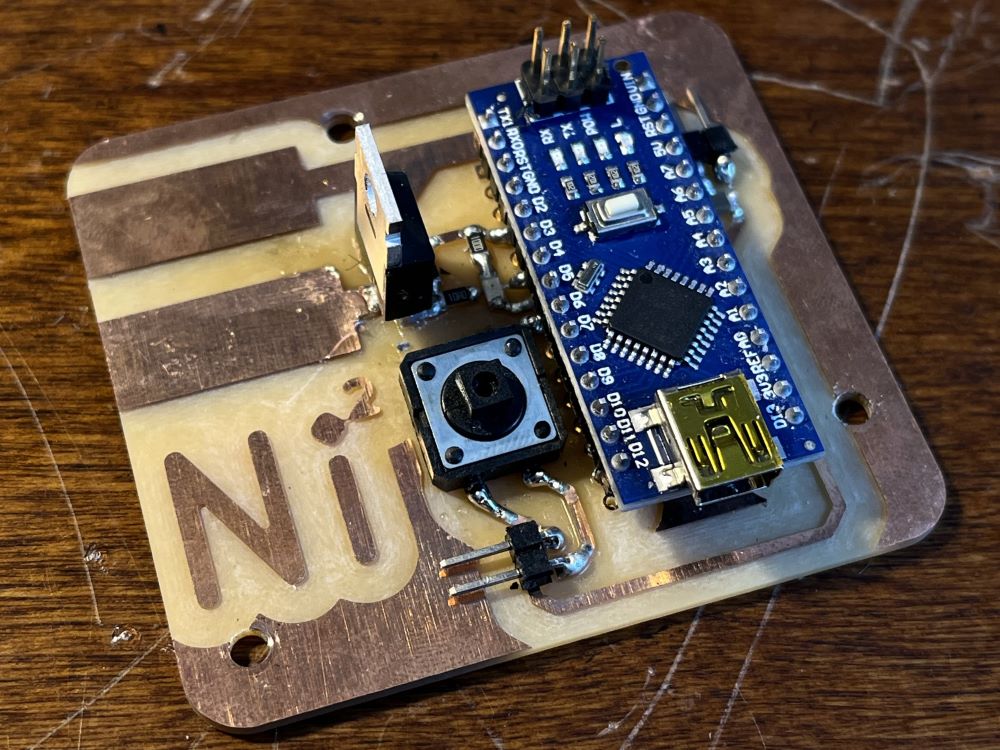

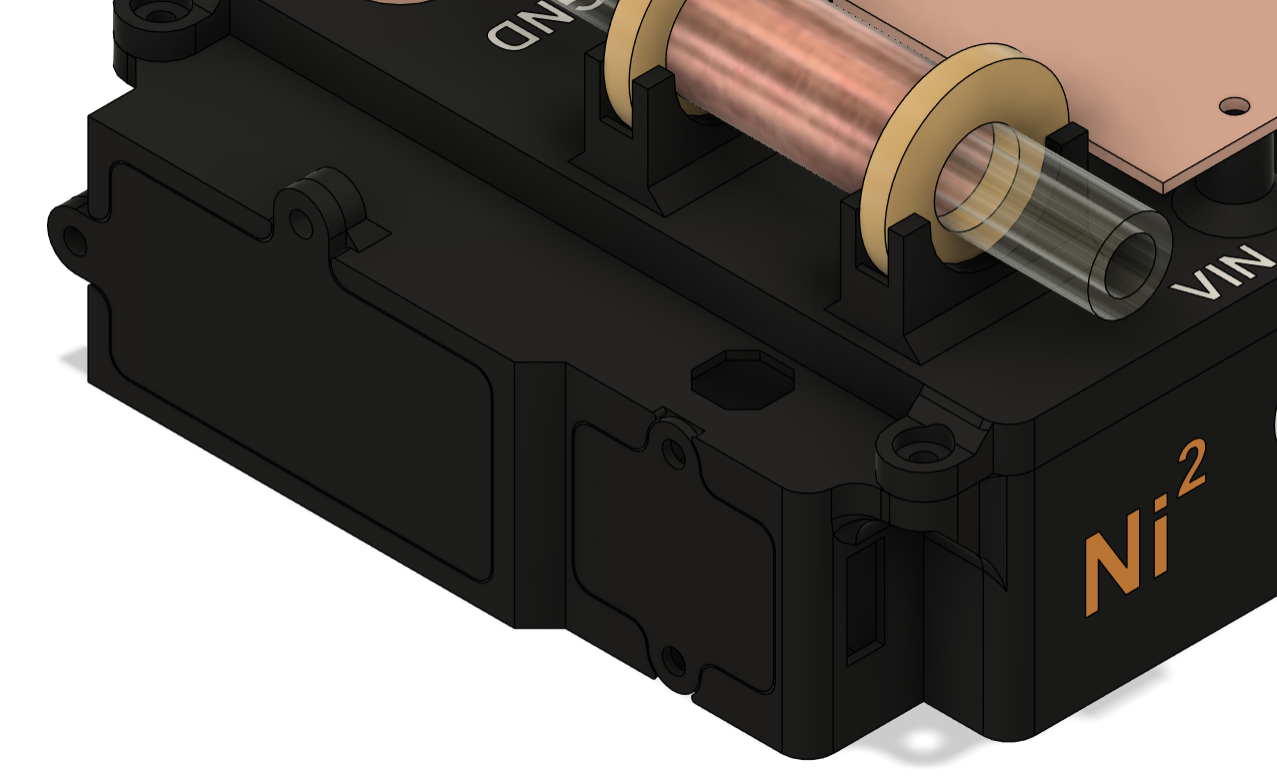

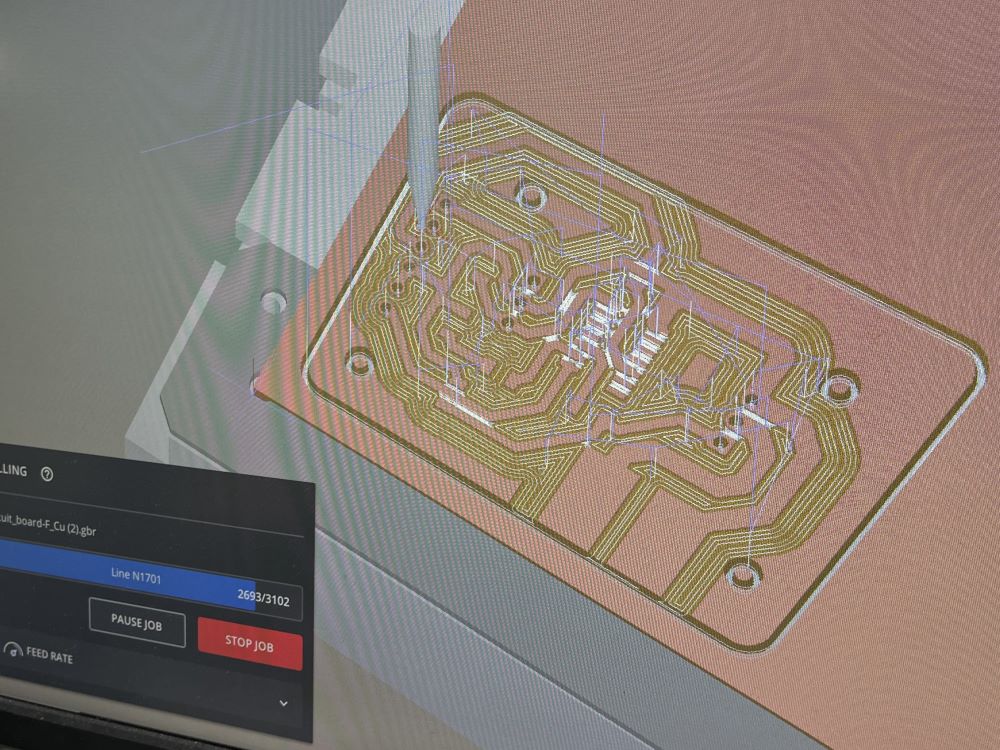

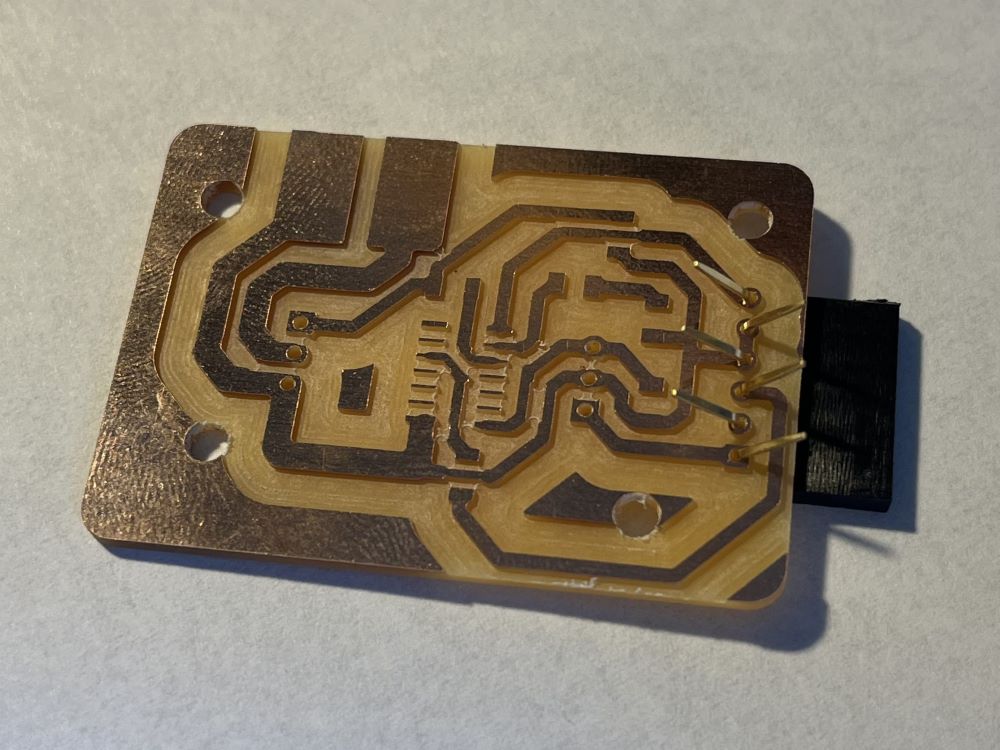

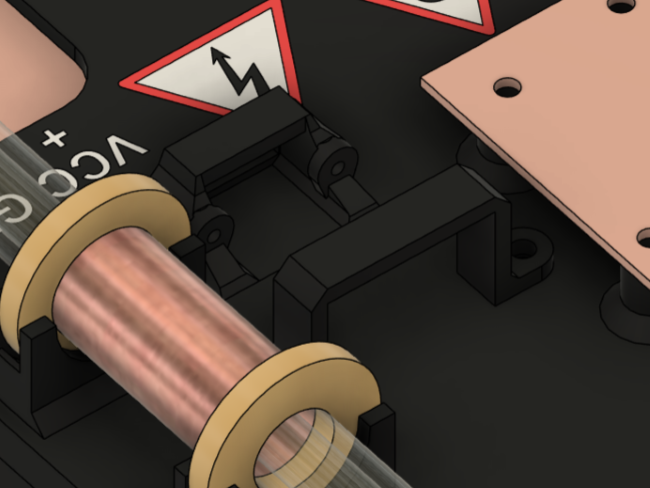

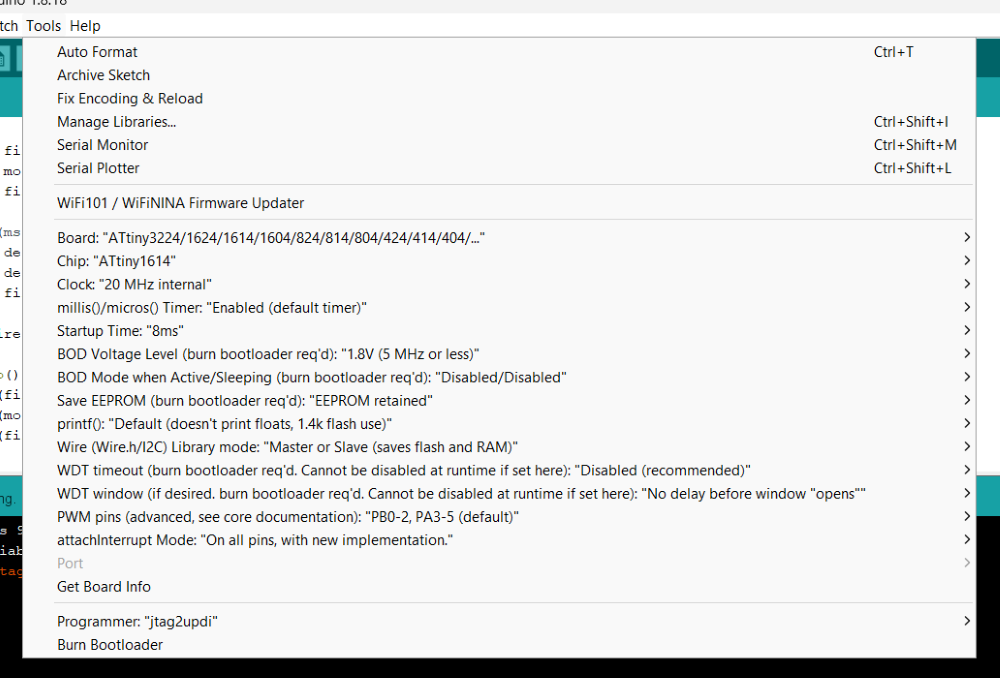

The Coil Gun Mk. 2 is a handheld electromagnetic device that launches ferromagnetic objects from the barrel via a charged capacitor bank discharged through a large inductor. It utilizes an Arduino Nano to toggle a MOSFET controlling the capacitor bank's connection to the coil. The device currently shoots at 12.4 mph, and is a second iteration of the Mk. 1 Coil Gun.