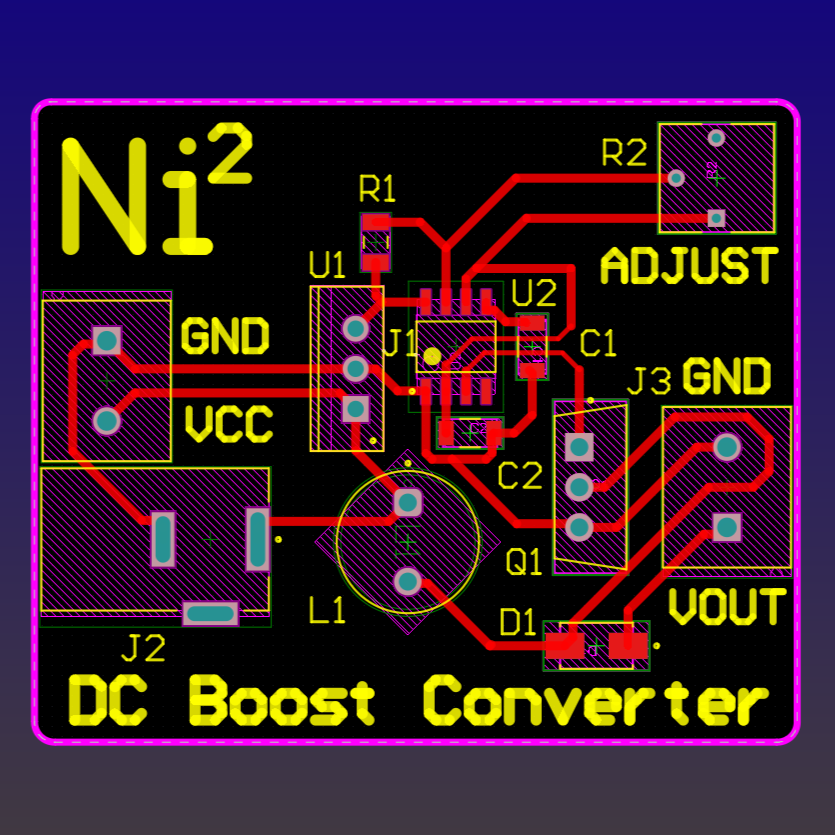

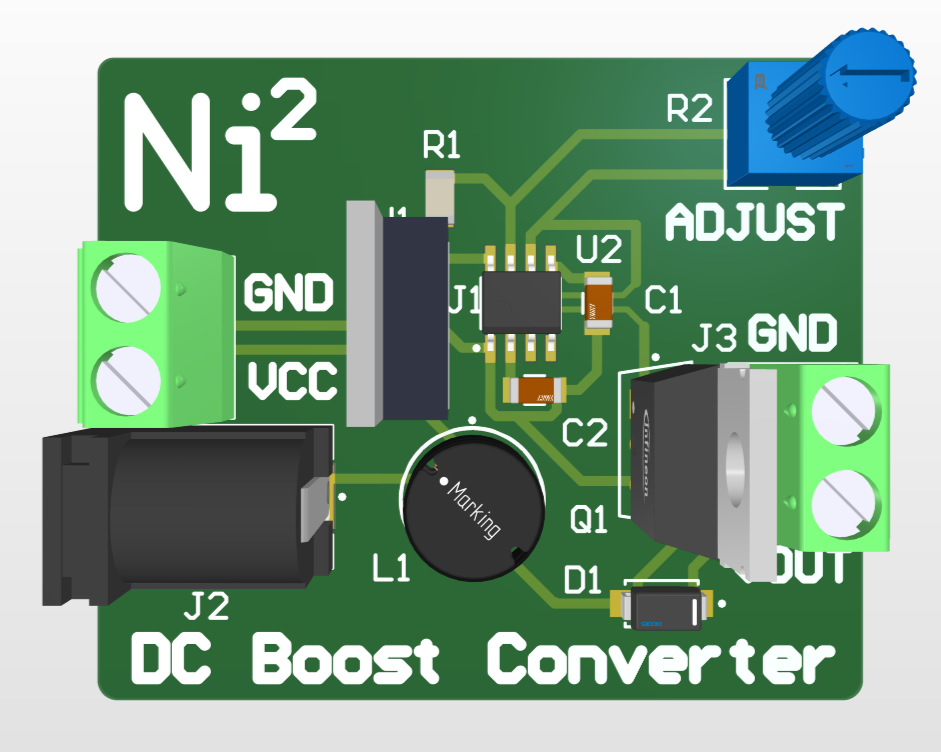

Variable Boost Converter

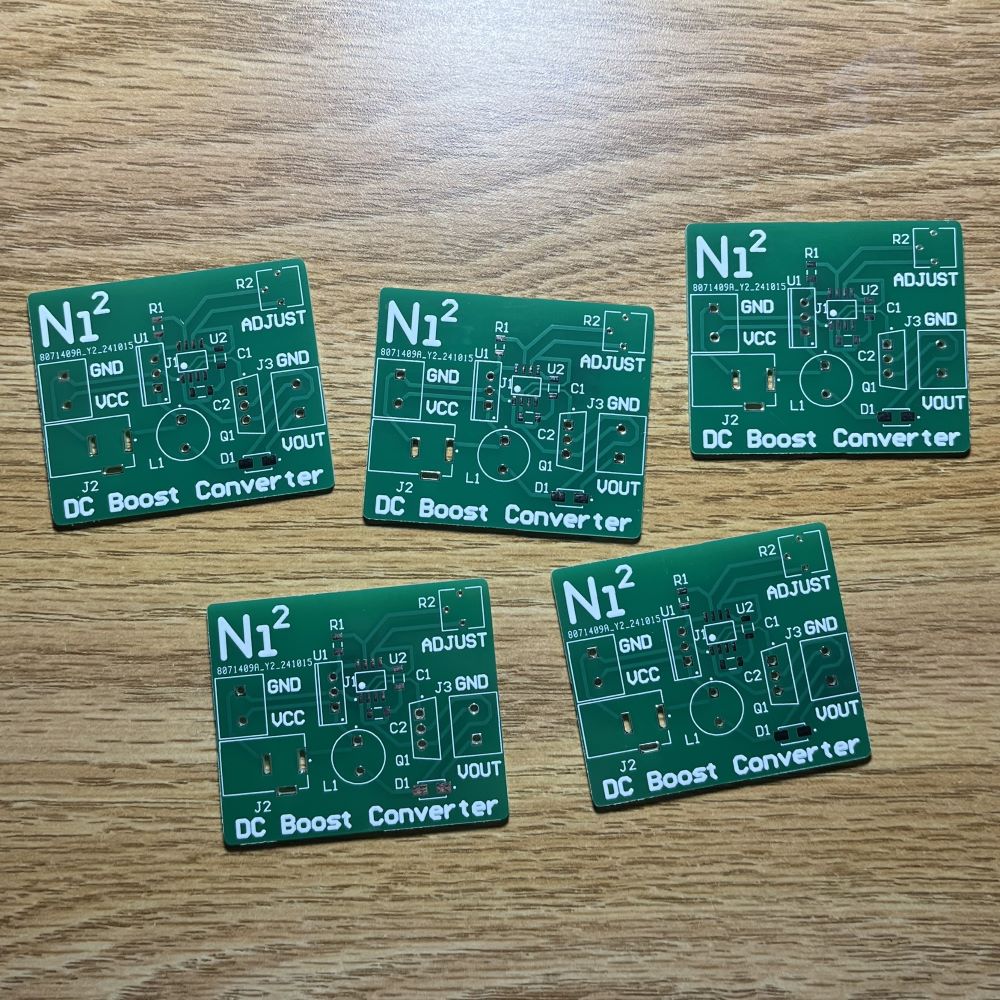

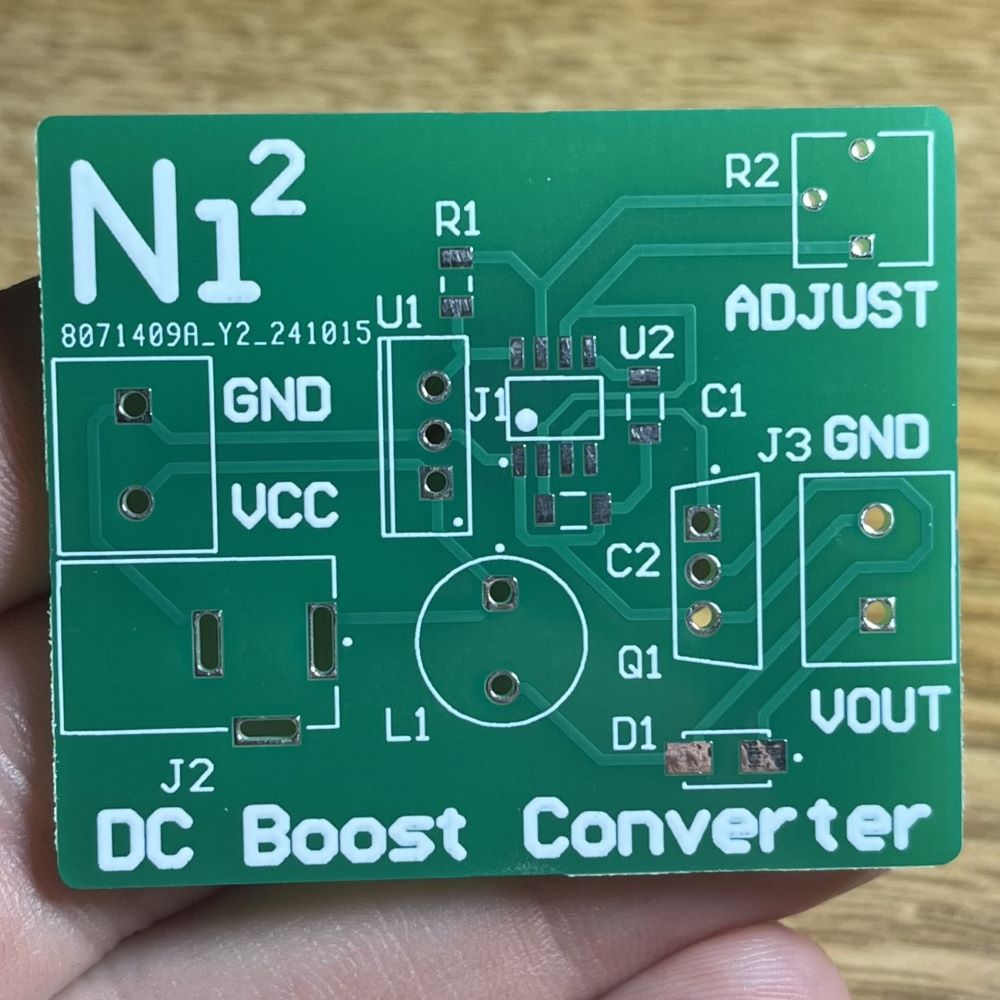

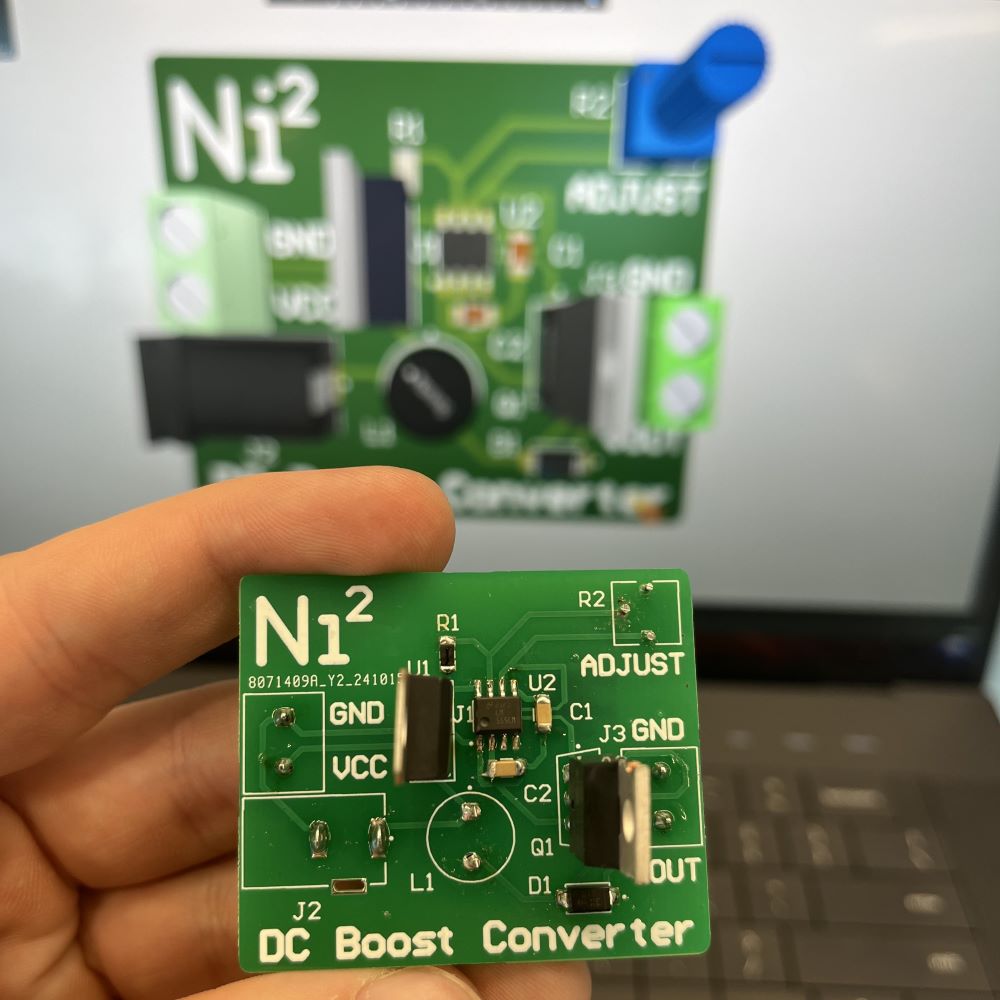

Circuit Board

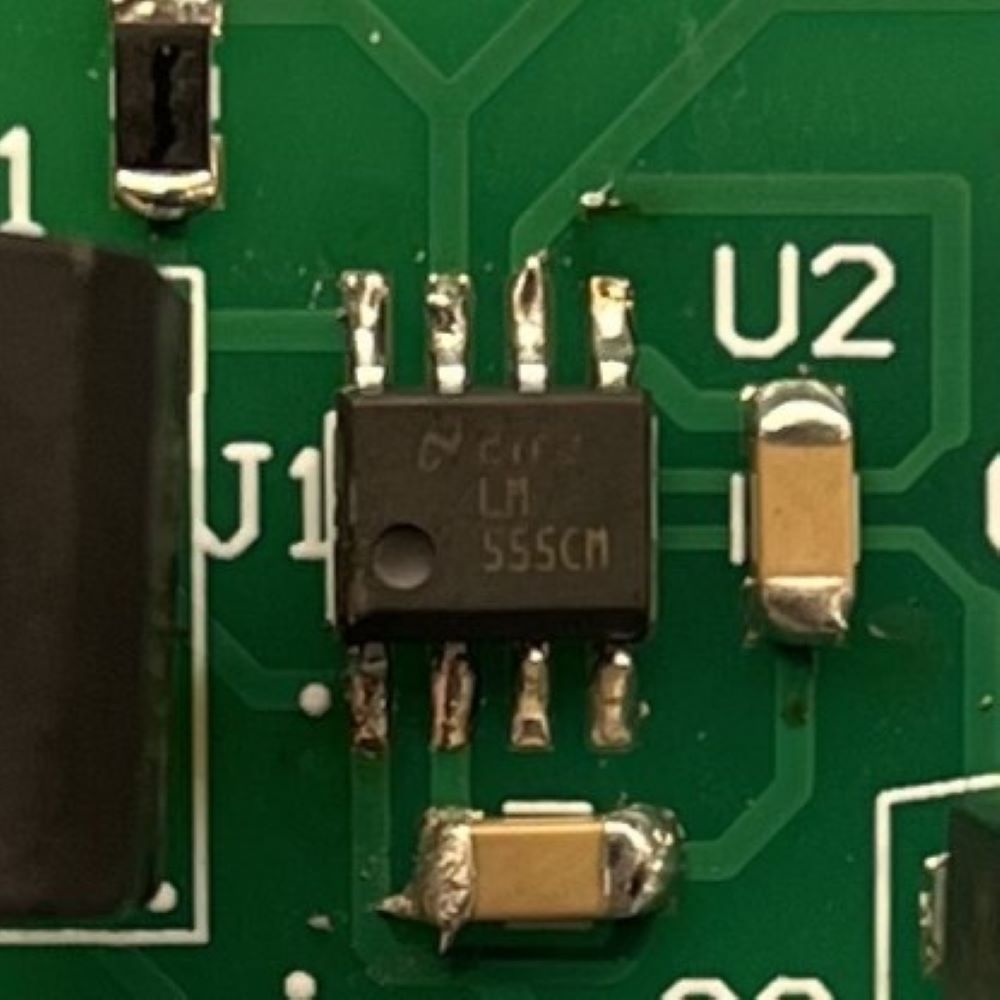

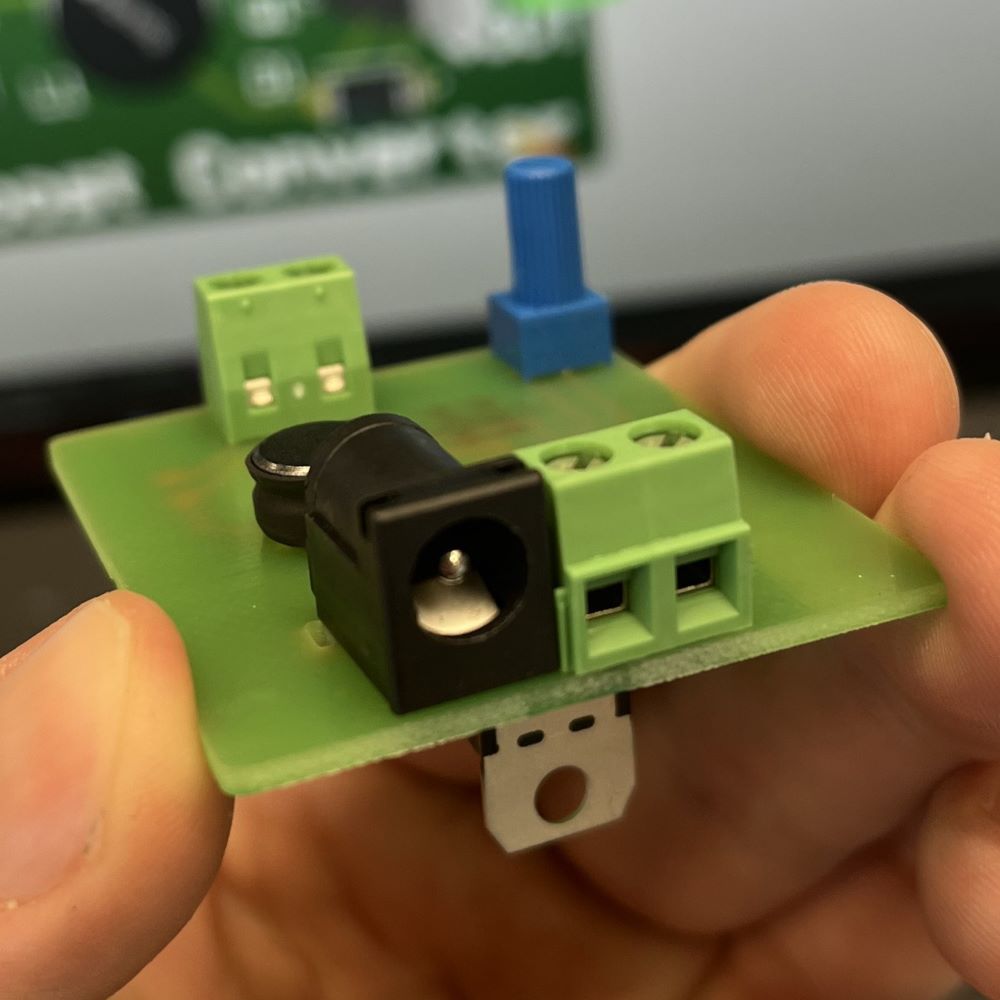

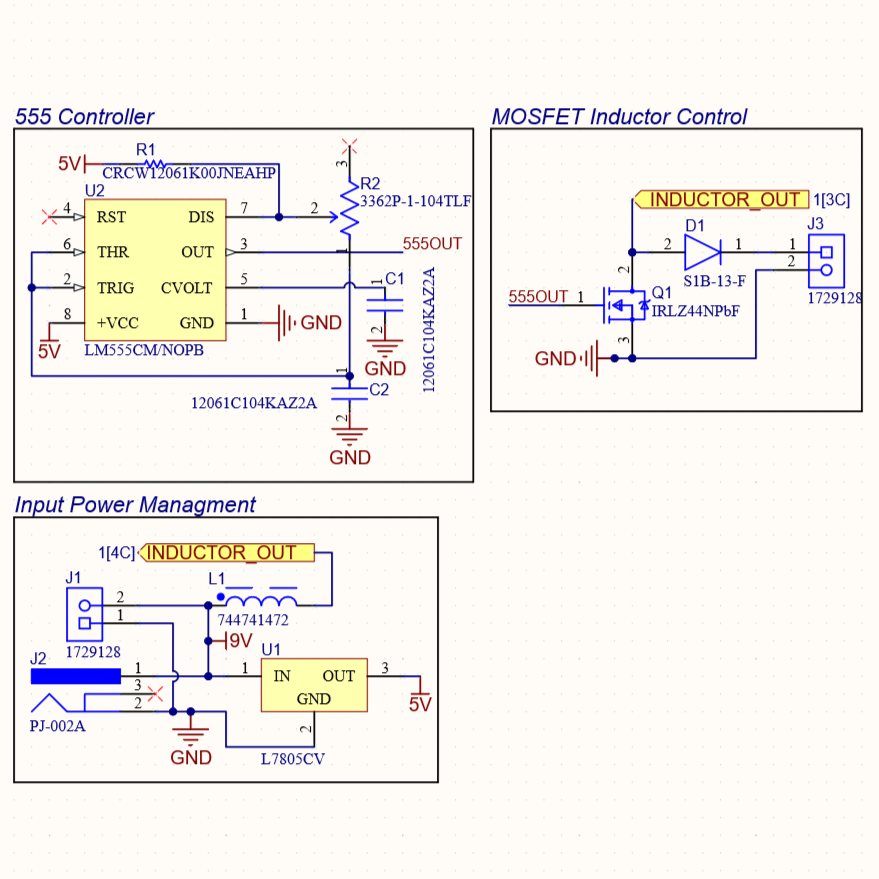

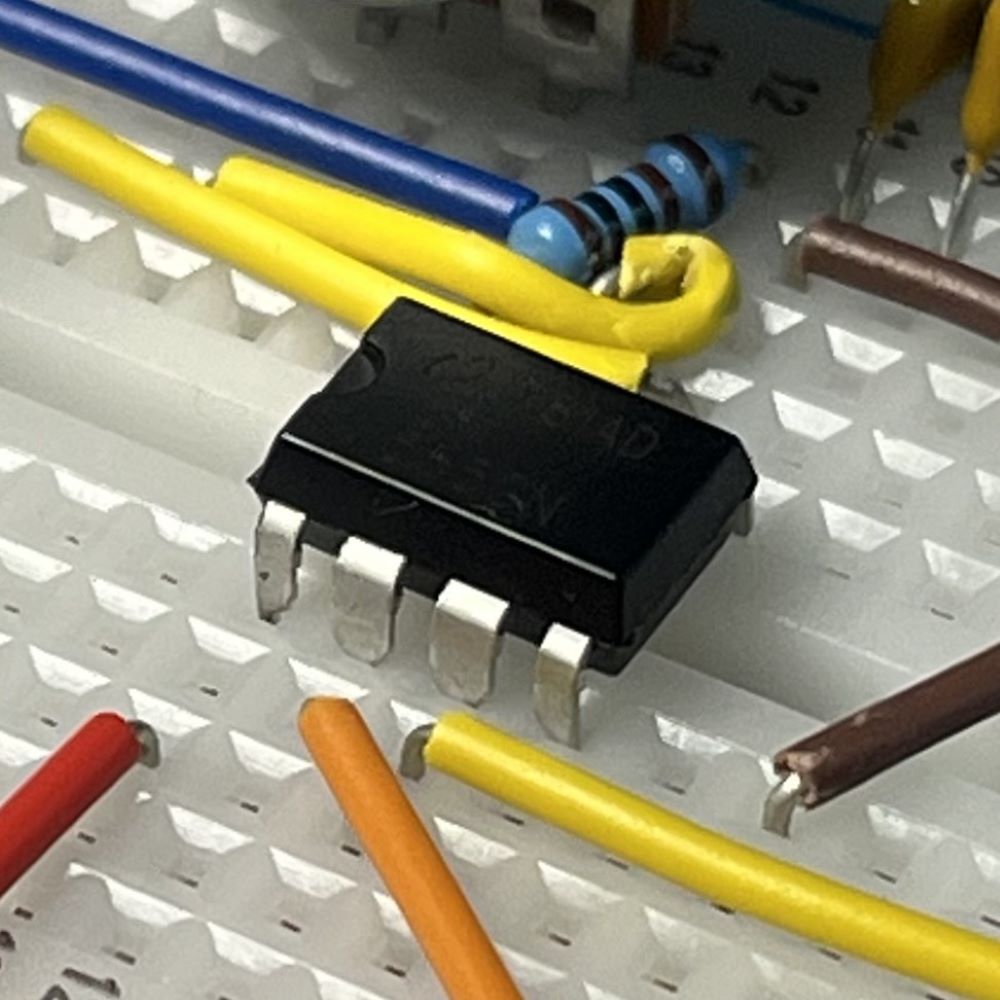

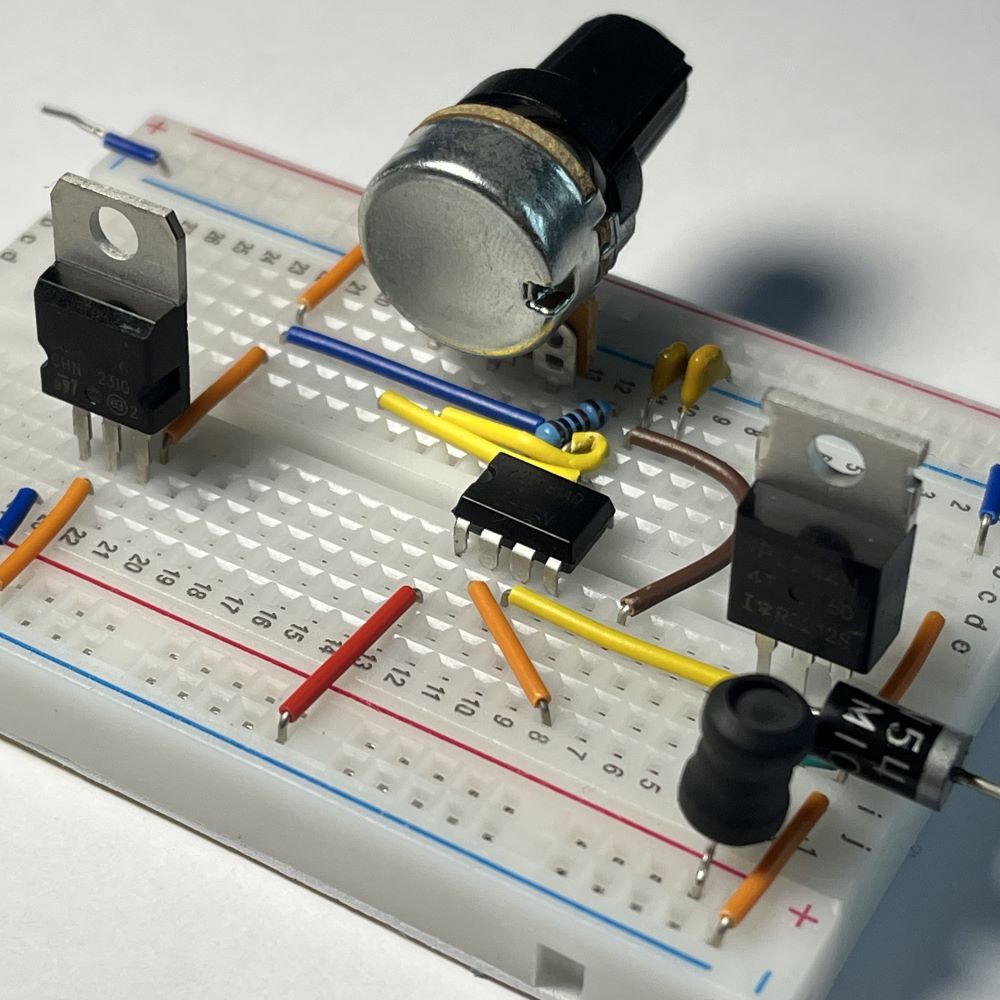

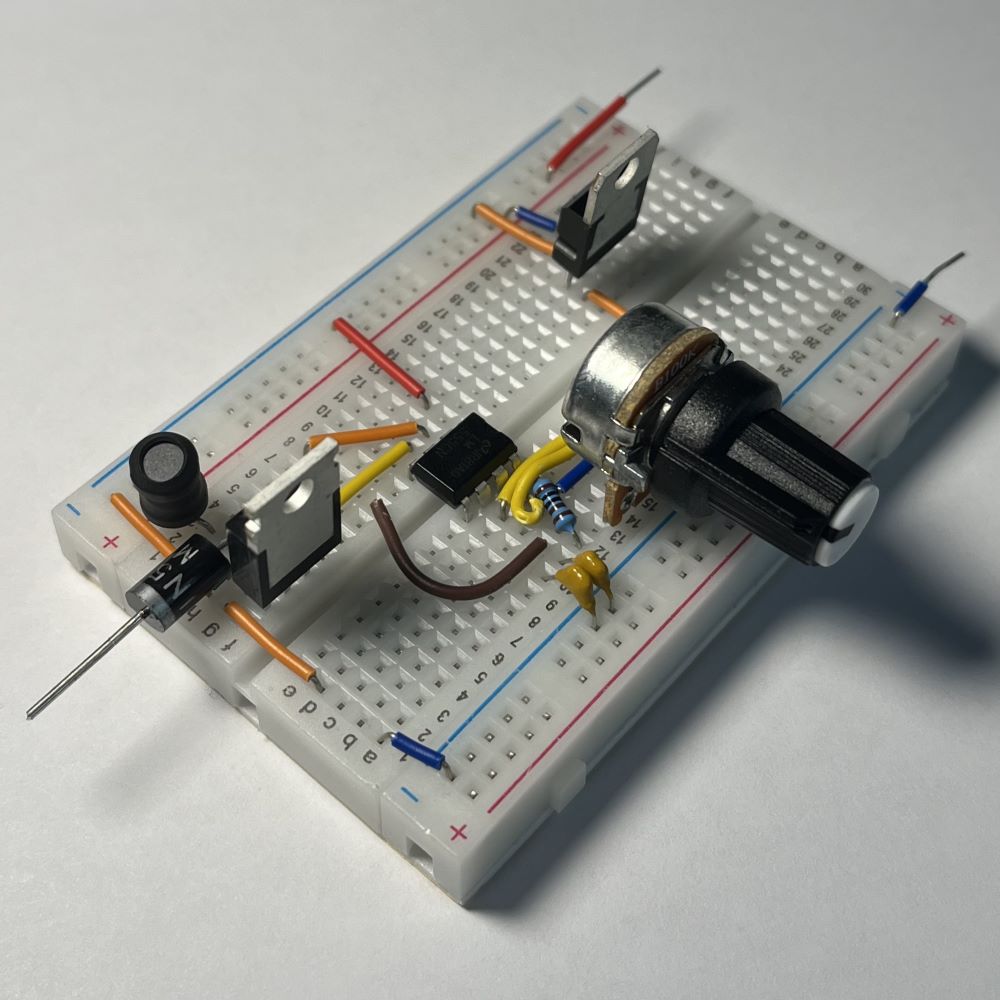

This DC-DC Boost Converter device able to multiply an input voltage up to 10x at the output. It utilizes primarily an LM555 IC in tandem with an inductor and MOSFET. Its output voltage is adjustable via the potentiometer.