Part 1 - The Idea

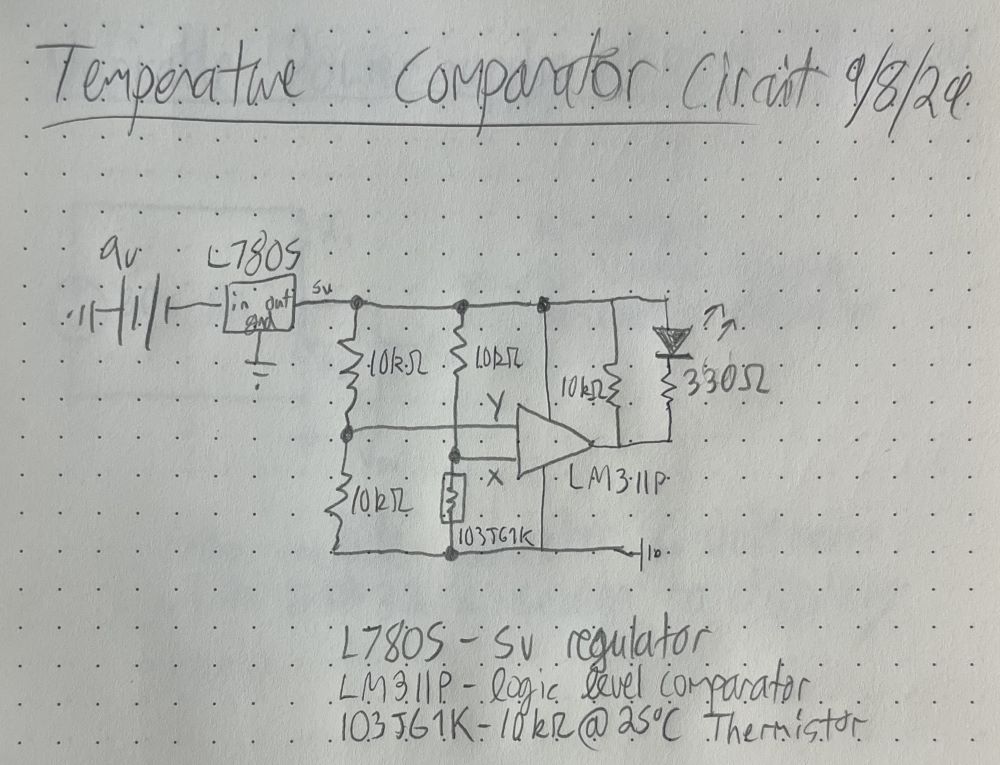

The idea to work on this circuit came from the book The Art of Electronics by Paul Horowitz and Winfield Hill. The book features

a simple thermistor/comparator circuit to turn an LED on. While I like their approach, not only did I want to target a different temperature

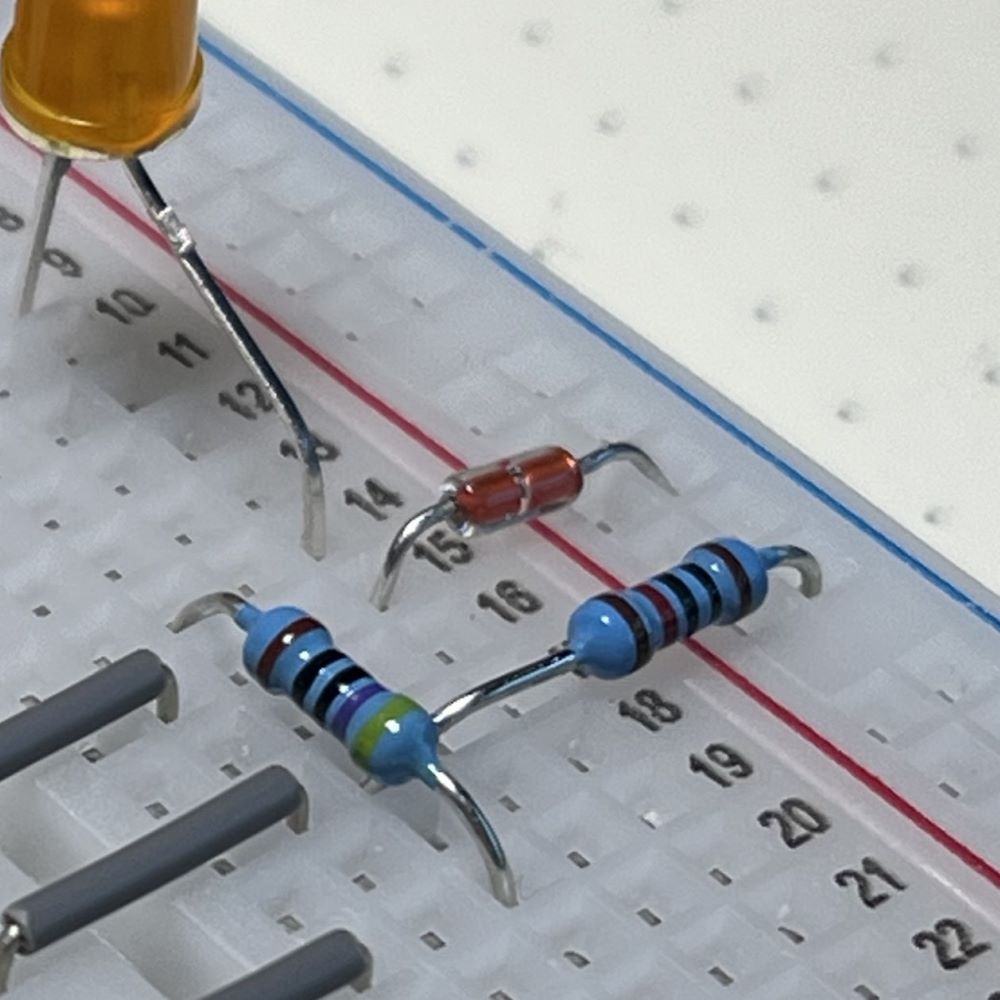

for the LED turn on, I also wanted to use different parts for both the comparator and thermistor. I chose to change my constant resistors to 10kΩ to target a temperature

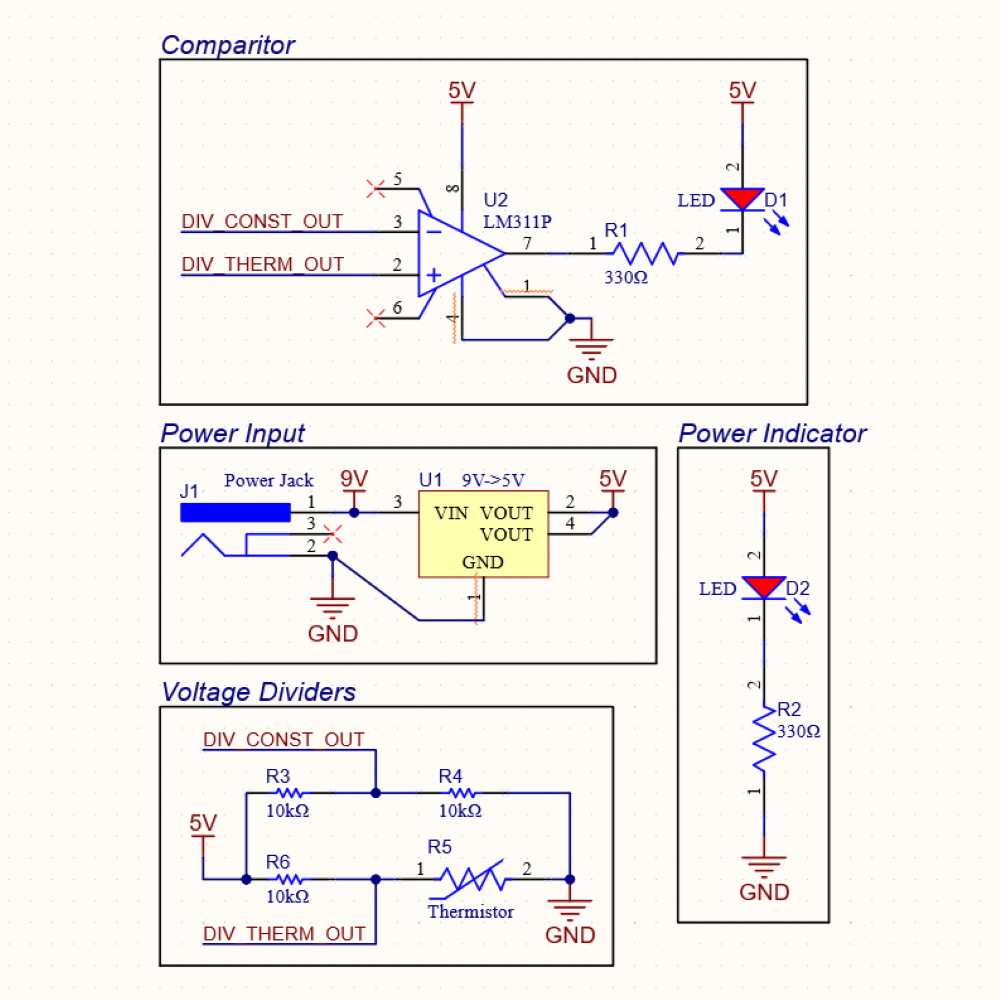

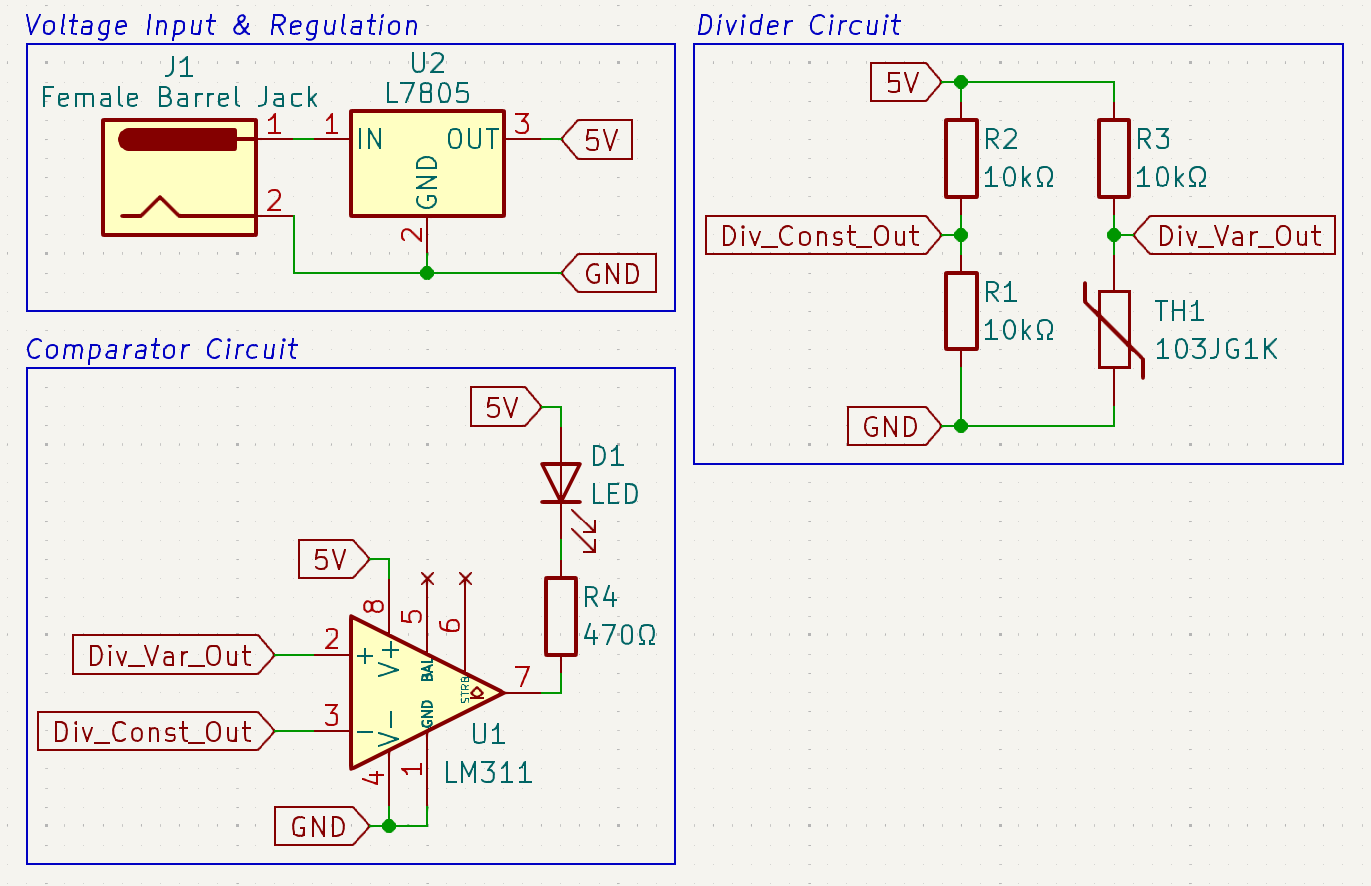

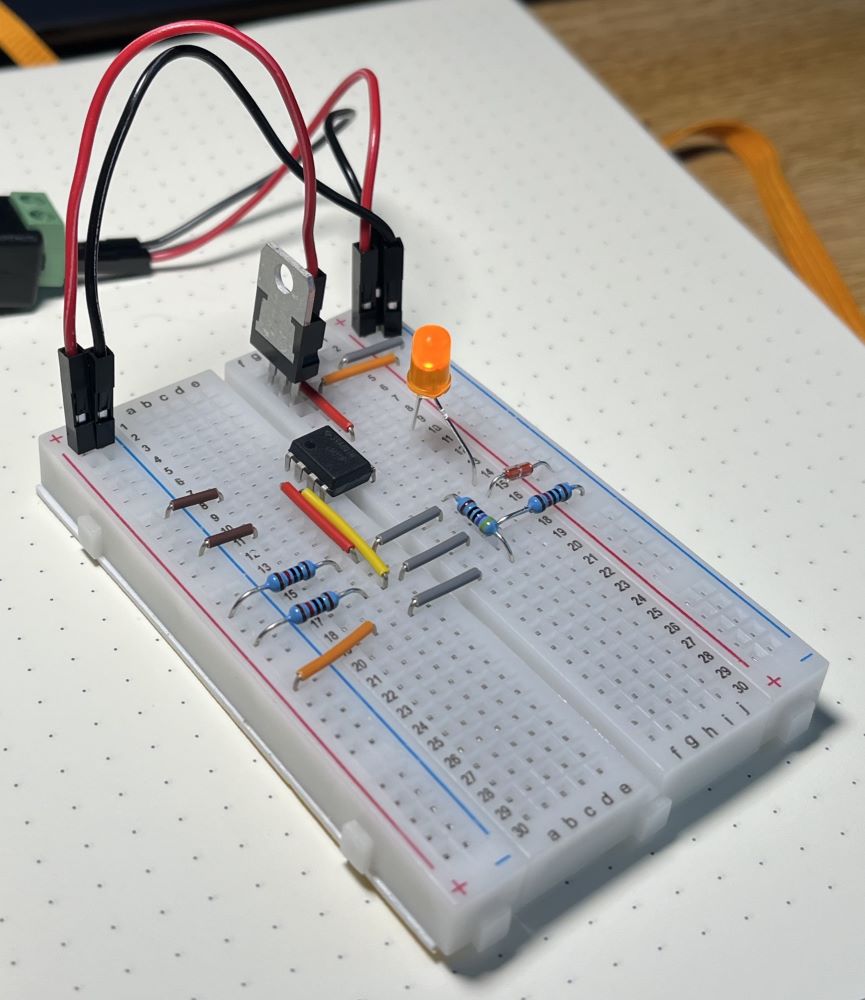

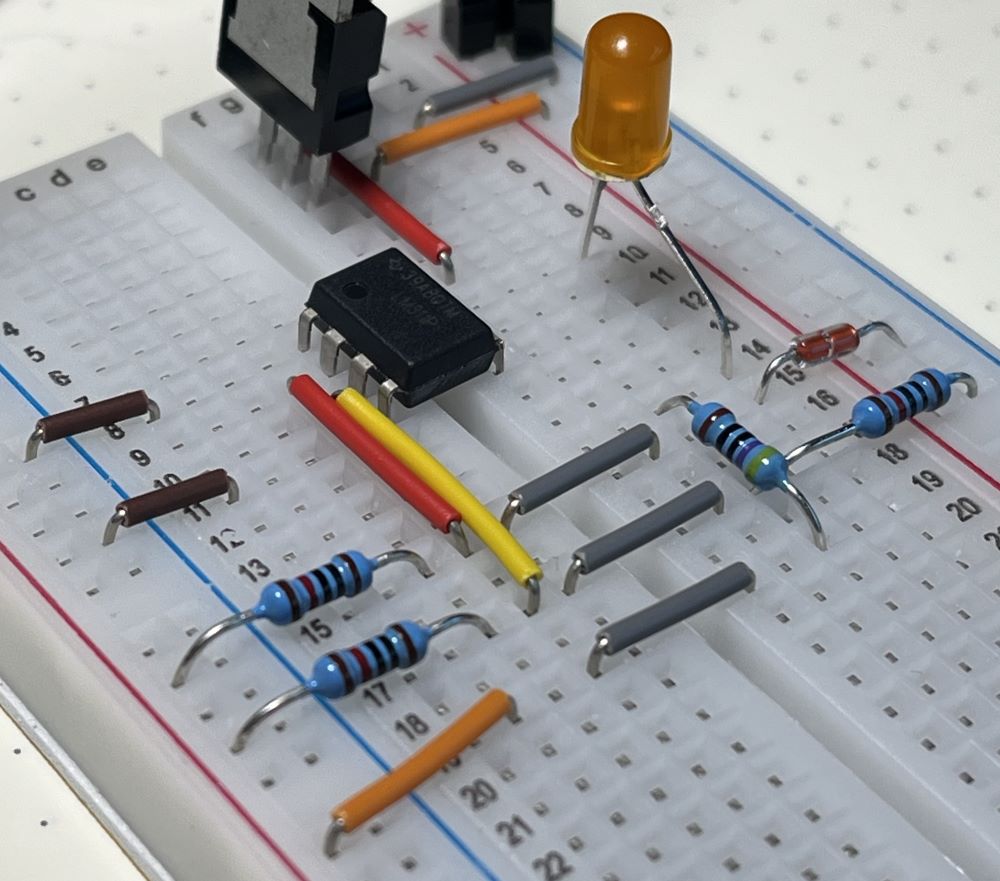

of 25°C instead of what they aimed for. The circuit itself, for some context, works as two separate

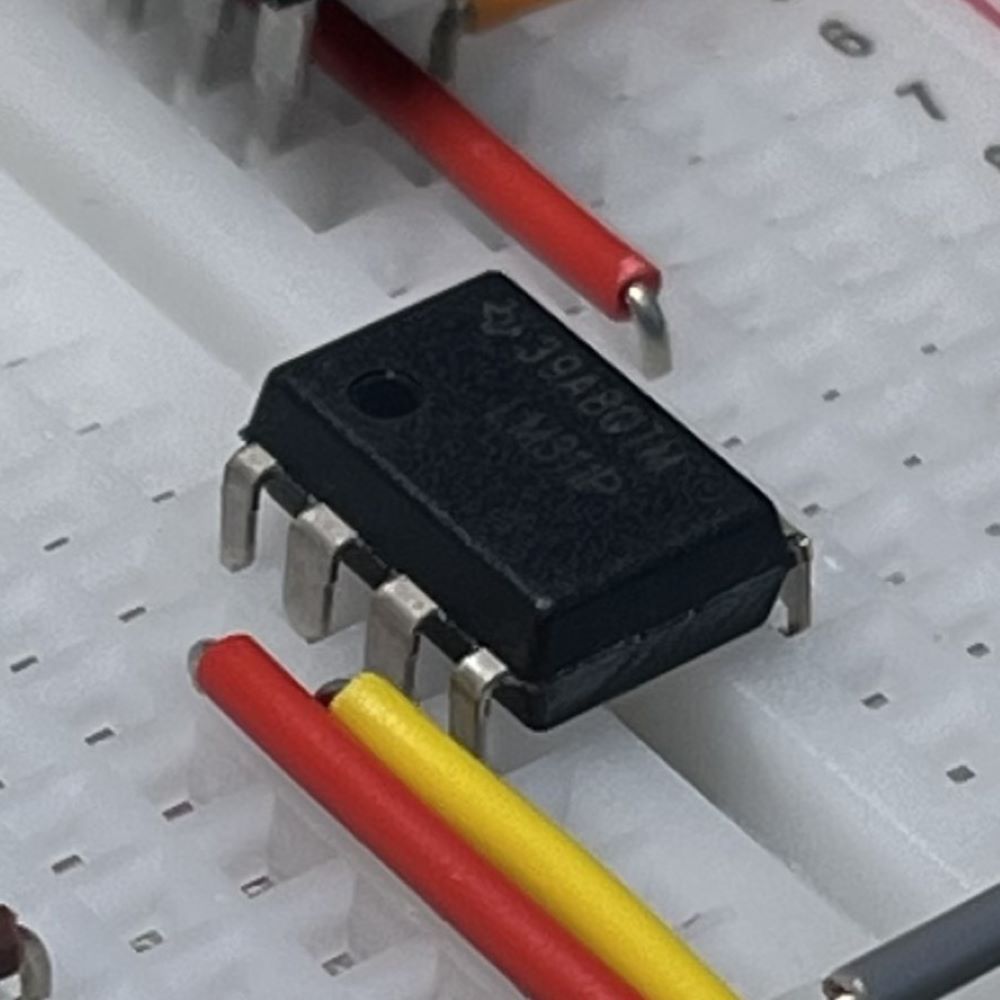

voltage dividers both connected to a comparator, a comparator which also has the cathode of an LED attached and a 5V line attached. One voltage divider is held constant, and the other divider's second resistor is a thermistor before reaching ground. As I'm inputting a voltage of 5V to both dividers,

the constant divider, which consists of two 10kΩ resistors, will output a constant 2.5V. This then goes to the Y terminal of the comparator. A second divider, consisting of

a 10kΩ resistor and then the thermistor, will output a variable voltage to the X terminal of the comparator. When the comparator reads X's voltage to be less than Y's, it will pulls the

LED's cathode connected to it to GND, thus allowing the LED to turn on. In my case, I want to have a thermistor that reads more than 10kΩ in conditions of greater than 25°C, that way

the LED will only turn on if the temperature is greater than 25°C (As then the second divider's second resistor will be greater than 10kΩ, thus outputting a lower voltage

from the divider, then pulling the LED to ground). A notable modification I made to the circuit is to have a 5V L7805 regulator to bring down the input voltage from

what will likely be a 9V battery to acceptable levels for the comparator and other components.