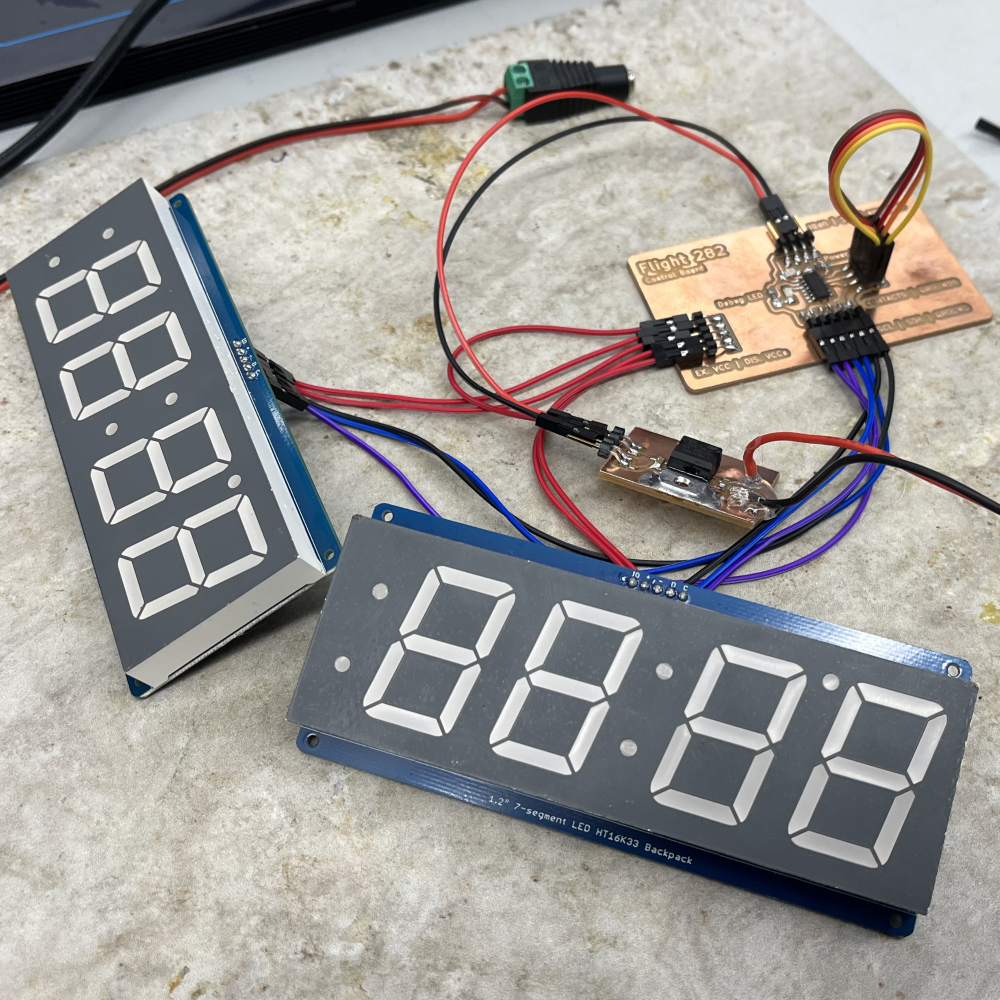

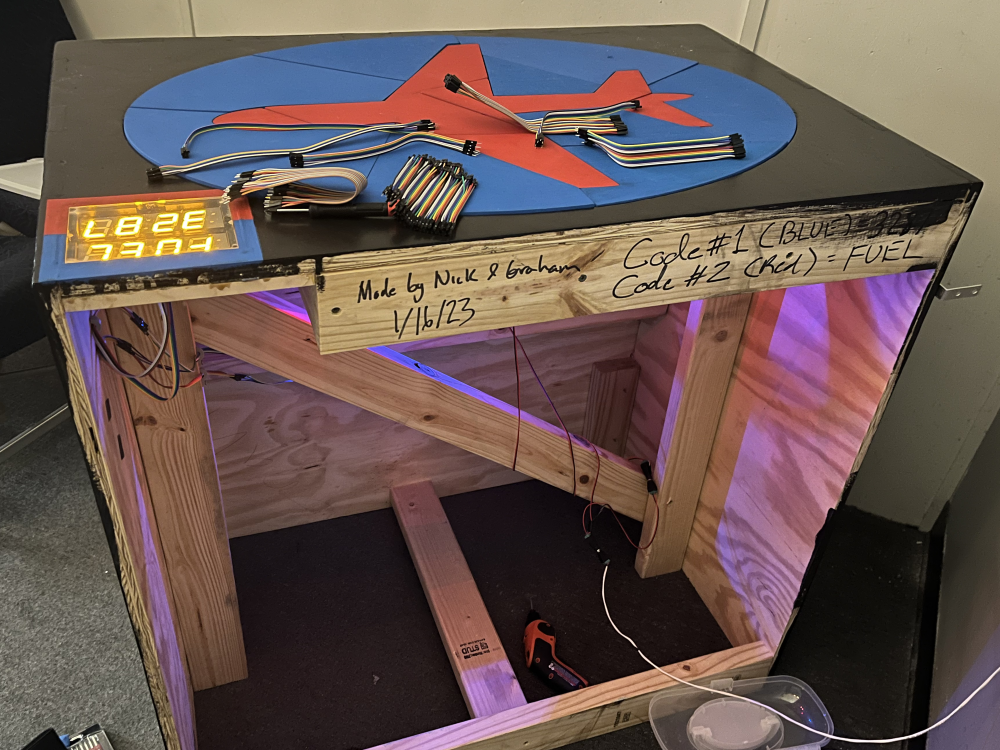

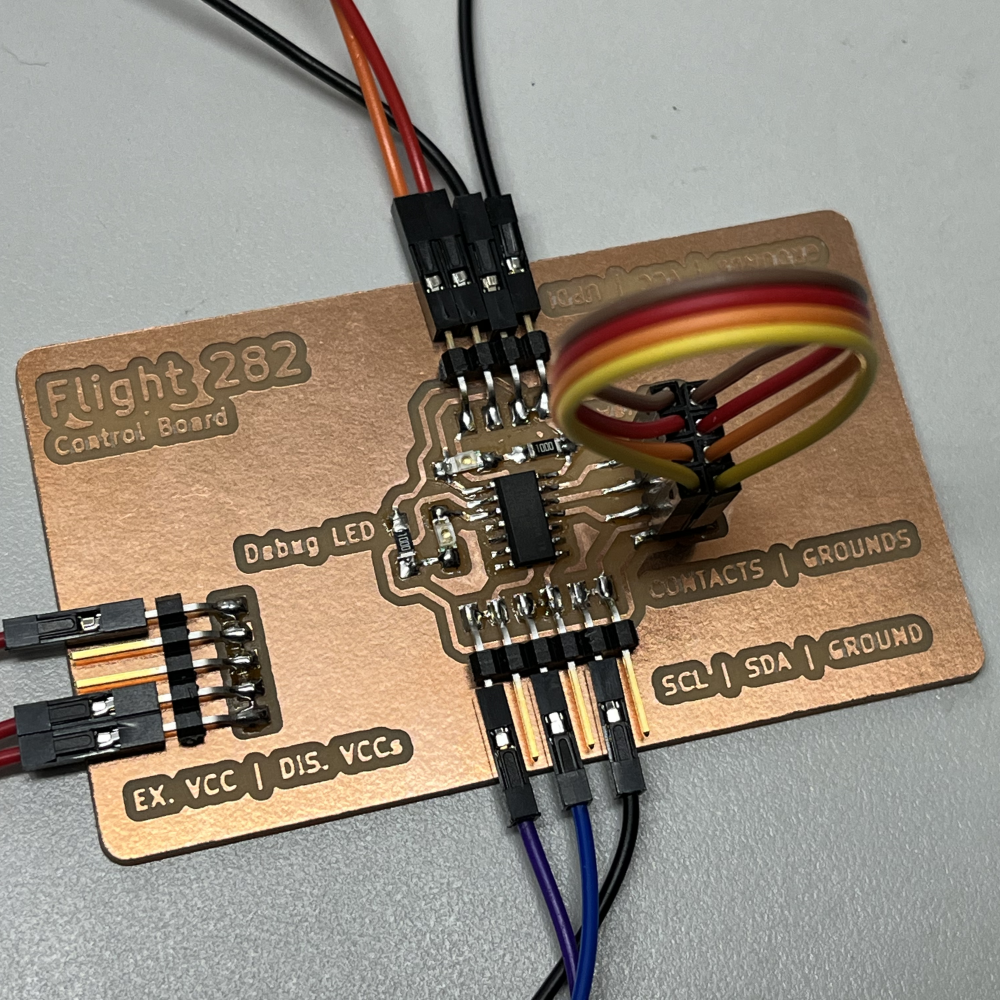

Flight 282 Puzzle

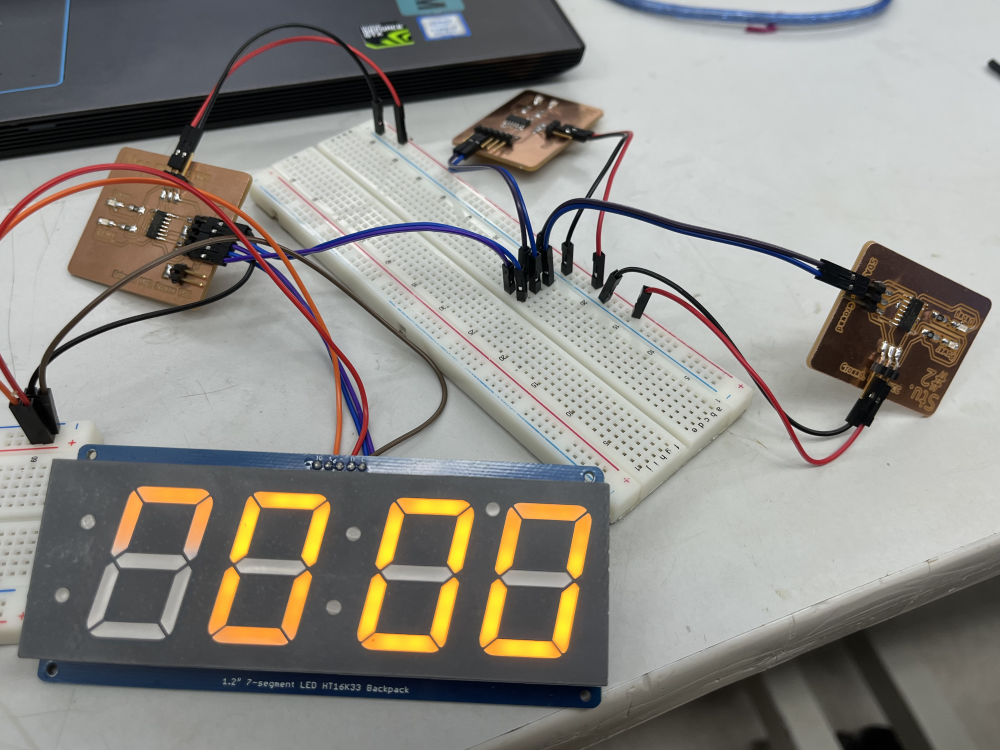

Circuit Board

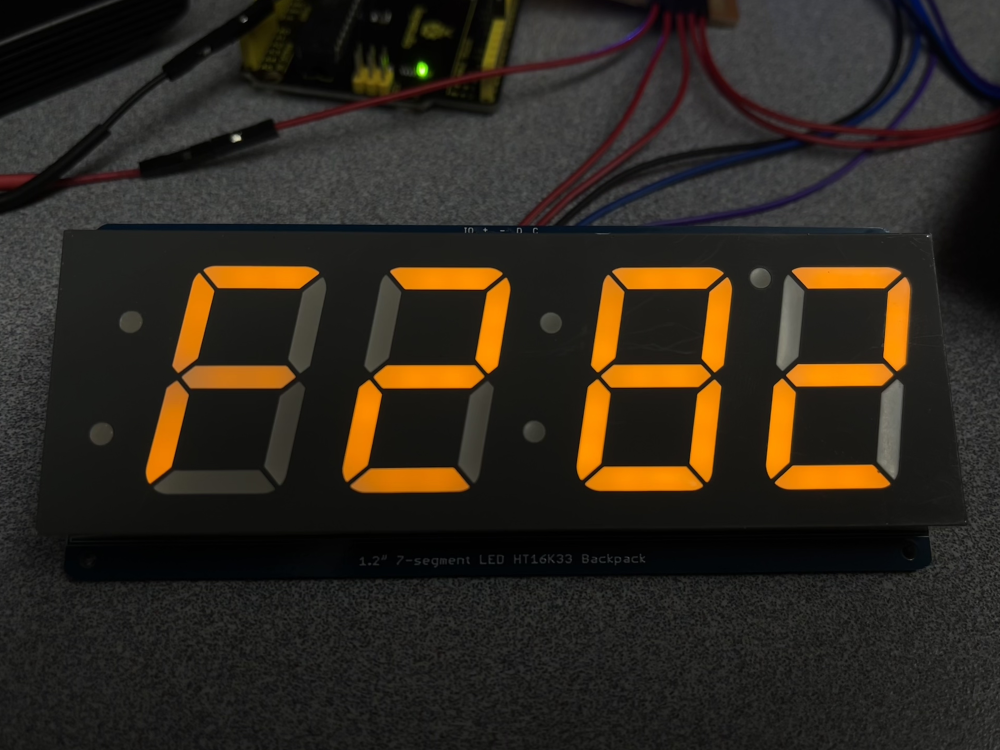

A puzzle I developed for my position as Puzzle Engineer at Escape Tactic, LLC. This puzzle required players to place 4 plane-shaped puzzle pieces in the right spots to trigger both a 4 digit code and 4 letter code to appear to continue the escape room. I designed, milled, and surface-mount soldered my own PCB to run the puzzle, including an ATtiny1614 microcontroller and i2C protocol for the 7 segment displays.