Desk Lamp

Device

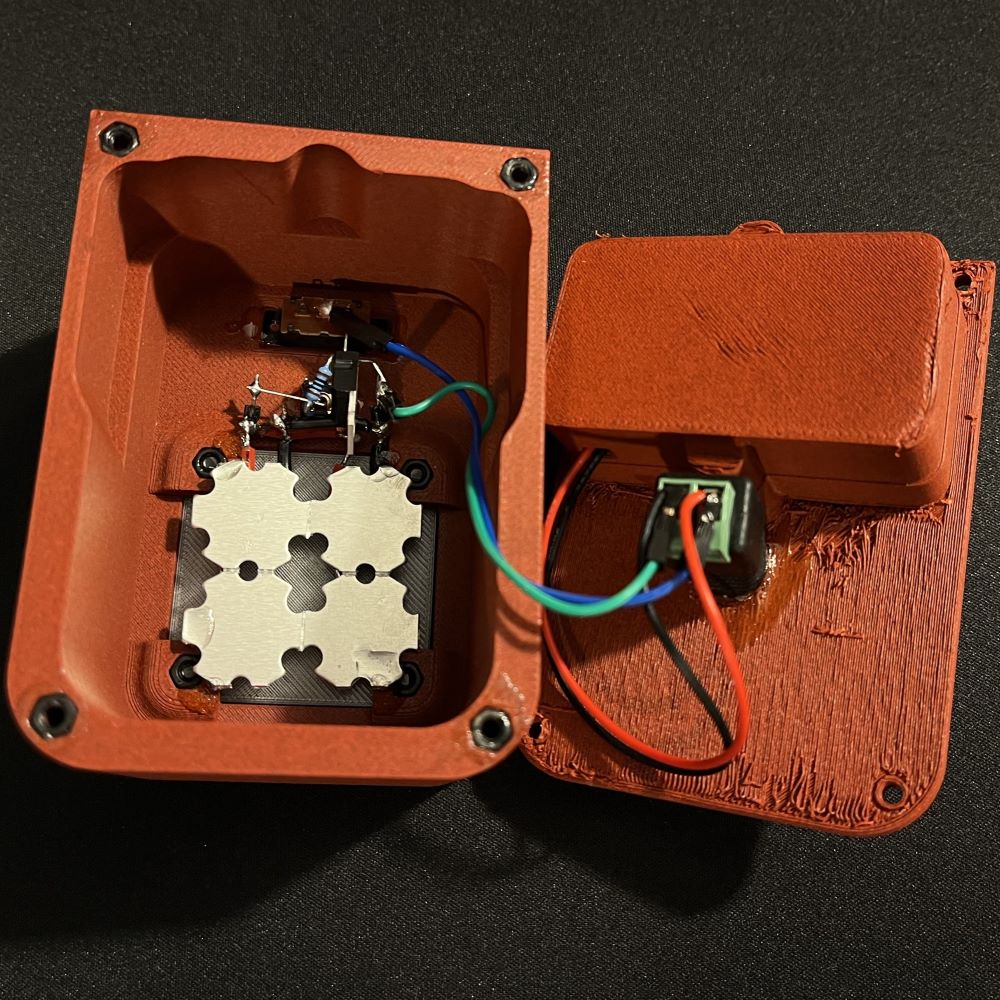

This desk lamp is a clean-looking battery or wall outlet-powered lamp. It can be turned on and off using a simple slide switch on the front and the brightness of the lamp can even be adjusted using the dial on the front. Electrically it utilizes a 5v regulator, potentiometer, special LEDs, and a slide switch.